Buy and Sell Used Batch Ball Mills | Perry Process

Paul O. Abbe Ball Mill, appears to be Model 81/2, measures 21 diameter X 28 long, rated for 42 gallon capacity, cu. ft. Previously used as dry grind mill to process precious metal scrap into a

WhatsApp)

WhatsApp)

Paul O. Abbe Ball Mill, appears to be Model 81/2, measures 21 diameter X 28 long, rated for 42 gallon capacity, cu. ft. Previously used as dry grind mill to process precious metal scrap into a

Ball Mill Savree . Crushed ore is fed to the ball mill through the inlet a scoop small screw conveyor ensures the feed is constant For both wet and dry ball mills the ball mill is charged to approximately 33 with balls range 3045 Pulp crushed ore and water fills another 15 of the drums volume so that the total volume of the drum is 50 charged.

Used Ball Mills for sale from Machinery and Equipment Used Ball Mills, ball mill fo sale. dia. feed inlet, leading to pressing.lt;/pgt; lt;pgt;Ball Mills Read more. ball mill for sale #187; My Blog. Feed sales account for ball mills The Planetary Ball Mill PM 100 CM Read more. used ball mill for sale #171; mines crusher for sale.

Metallurgical ContentTypes of Ball Mills Ball Mill GrindingExample of Plant Capacity GainsBall Mill SpecificationsCompare Type of Mill DischargeGrate Discharge Ball Mill CapacitiesGrate Discharge Ball Mill Arrangement amp; Dimensions Allow me to compare: Ball mills can be of the overflow or of the grate discharge type. Overflow discharge mills are used when a product with high specific surface is

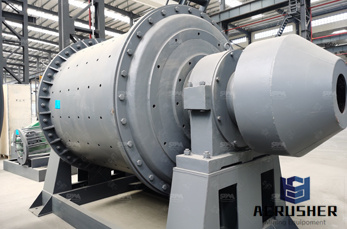

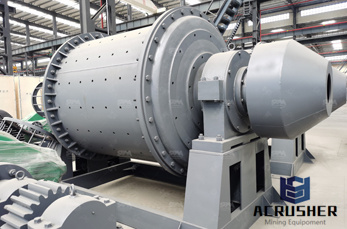

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50 % of the mill volume and its size depends on the feed and mill size.

220V Electric Feed Mill Wet Dry Cereals Grinder Ri . Die could do with a good clean out and out casing has some marks and could do with a good clean. 220V Electric Feed Mill Wet in good condition other items avalible if you want any other items i will discount on postage. due the post office losing items . i always obtain proof of postage. if you send items back i will not pay for postage

12 x 14 ft ( x m) Marcy Ball Mill with 1,500 HP 12 ft diameter and 14 ft length mill shell Feed and discharge heads Shell with steel liners installed (spare shells available at additional cost) 2 piece bull gear (spare available at additional cost) S...

Ball mills of greater length are termed tube mills, and when hard pebbles rather than steel balls are used for the grinding media, the mills are known as pebble mills. In general, ball mills can be operated either wet or dry and are capable of producing products on the order of 100 pm.

Inventory ID: 6CHM01. 3 Units UNUSED FL 26 x 43'' Dual Pinion Ball Mill with 2 ABB 9,000 kW (12,069 HP) Motors w/ ABB VFD for Total Power of 18,000 kW (24,138 HP)

Fl ball mill for cement grinding the fl ball mill is designed for in the mill inlet chute 83m x 274m 6 x 9 25 hp feed chute and steel liners is pleased to announce the availability of cemtec grinding mills to the north american mining and cement industry cement ball mill Air swept ball mill inlet chutes ball mill inlet

General design for {wet and dry} ball mill General description for ball mill 1 Bearing 2 Mill Shell 3 Driver Types of driver is { Central driver and Gear rim / pinion} 4 Inlet Types of inlet is { Inlet type, Inlet chute, and inlet screw } 5 Outlet Types of Outlet Over flow mills with/without screen cage Discharge diaphragm outlet casing Central discharge 6

Used, unused and refurbished ball mills available for a fraction of the cost of new. USbased Phoenix Equipment is a global buyer amp; seller of ball mills, as well as other industrial equipment. Check out our extensive inventory or talk to a knowledgeable representative today.

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming

dry ball mill feed inlet for sale. Ball mills of greater length are termed tube mills and when hard pebbles rather than steel balls are used for the grinding media the mills are known as pebble mills In general ball mills can be operated either wet or dry and are capable of

Air Swept Dry Ball Mill Feed Inlet Air swept dry ball mill feed inlet you4baselch air swept mill mineral processing metallurgy in an airswept mill the body of which does not differ significantly in general design from a trunnion overflow mill a powerful stream of air is passed through the mill and removes the finer particles produced .

Fitzpatrick Mill Chilsonator IR520. Manufacturer: Fitzpatrick Model Number: IR520 Frain Number: 5H7500 Fitzpatrick Model IR520, 316 stainless steel, roller compactor, chilsonator rated up to 150kg of product per hour depending on materials, application, machine configuration and environment being run in. (2) screw feed design has 13quot; long x 9quot; wide x 10quot; deep ID stainless steel product

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

always has the largest selection of New or Used Feed Mixers Equipment for sale anywhere. 11. 1. Stock #: 35963 . 39,900. 11. Make an Offer. Call for Prices. 39,900. Make an Offer. Get Financing as low as /mo* 2016 LIET SOLOMIX 21800VLHK . Feed Mixers .

Dry ball mill is widely used in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic industry. Working principle: Ball mill machine is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and electronic control.

WhatsApp)

WhatsApp)