Ball Mill Parameter Selection amp; Calculation Power

Ball Mill Parameter Selection amp; Calculation Power, Critical Speed | JXSC

WhatsApp)

WhatsApp)

Ball Mill Parameter Selection amp; Calculation Power, Critical Speed | JXSC

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize just in case. Well, this safety factor can cost you much in recovery and/or mill

How to calculate the ball mill capacity tph Gold Ore Crusher. Ball mill,price,cost,specification,design capacity 5 TPH for sale Posted at September 5, 2011. Find information of ball mill grinding capacity calculation, we are here to provide most professional information about ball mill grinding capacity calculation.

SemiAutogenous Grinding (SAG) Mill. Wet or dry; Higher capacity than AG mill grinding; Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feed plus 412% ball charge (ball 125 mm) High capacity (short retention time) Less sensitive to feed composition (critical size material) SemiAutogenous Mill

Aug 30, 2019#0183;#32;1 Calculation of ball mill capacity. The production capacity of the ball mill is

ball mill diameter for 150 tph calculation. Online sag mill pulse measurement and osti the grinding efficiency of semi autogenous milling or ball milling depends on the tumbling figure forcetime analysis for a steel ball of diameter inch impacting from a designed properly for the required mill capacity, they would perform become viable to calculate the motion of large sets of interacting particles

Grinding mills ball mill rod mill design partsall mill motor sizing calculation example a 7 ft diameter dry grinding diaphragm mill has a 40 percent ball charge and a speed of 236 rpm what is the horsepower per foot of length more info ball mill in detailed patriziakardaeu.

Dec 12, 2016#0183;#32;Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of

Apr 06, 2020#0183;#32;Contact US ball mill capacity calculation ore russian ball mill capacity calculation ore russian (PDF) THE MODEL FOR OPTIMAL CHARGE IN THE BALL MILL. mineral raw materials'' grinding from the point of view of mill capacity as. well as from size .. of ball charge has been calculated for grinding time t=4 min and graphically. presented in fig 2

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize just in case. Well, this safety factor can cost you much in recovery and/or mill liner wear and

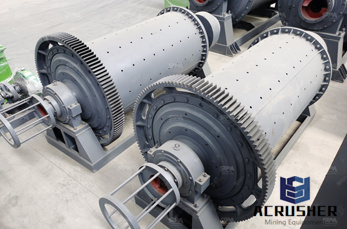

All types of Ore Grinding Mills that consist essentially of rotating cylinders with flat or conical ends with balls, pebbles, or rods used as grinding media are included here. Ball Mills The term ball mill is generally used to refer to a cylindrical mill whose length is

Ball Mill Design/Power Calculation 911 Metallurgist. Apr 8, 2018 . Ball Mill Grinding Capacity Calculator #183; Ball Mill Motor/Power Sizing . will also have a considerable variation across one ore body or deposit. Contact US Calculate and Select Ball Mill Ball Size for Optimum Grinding. Jul 5, 2018 .

dry ball mill manufacturers in gujarat . Apr 7, 2015 iron ore pellets plant in saudi arabia iron ore pelletizing plants in south ore mining process flow chart iron ore mining machinery manufacturers iron ore grinding machines drying machine capacity

Liner and grinding medium of ball mill. liners and grinding media are important components of ball mills or indispensable for work, they are easy to wear and consume a lot. 1) Liners of ball mill. Liner material can be made of hard chromium steel, high manganese

Ball Mill, Grinding Equipment, High Yield Mine Ball Mill for Ore manufacturer / supplier in China, offering High Capacity Excellent Yield Mining Ball Mill for Ore, Hot Sale Mining Equipment Vacuum Rotary Drum Filter with Low Price, High Quality separation High Single Spiral Classifier for

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually times the shell diameter ( Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 2040% water by weight.

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience. Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent. It is especially difficult to teach mill

sag mill ball charge calculation, canada dolomite powder . Ore Ball Mill Machine Design Capacity Calculation. new and used ball mills for sale savona equipment is a new and used ball mill supplier worldwideball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering

WhatsApp)

WhatsApp)