Types Of Coal Use In Brick Industry

types of coal use in brick industry. MercuryinurbansoilswithvarioustypesoflanduseinBeijing...:201228in Beijing was affected by both types of land use and the

WhatsApp)

WhatsApp)

types of coal use in brick industry. MercuryinurbansoilswithvarioustypesoflanduseinBeijing...:201228in Beijing was affected by both types of land use and the

type of coal use in bricks manufacturing. Bricks in the metallurgy and glass industries are often used for lining furnaces in particular refractory bricks such as silica magnesia chamotte and neutral chromomagnesite refractory bricks This type of brick must have good thermal shock resistance refractoriness under load high melting point and

Manufacturing Fired Bricks Containing Coal Combustion Byproducts. Developing technologies that would use large amounts of coal fly ash shale from Global Clay Marseilles (GCM), a brick manufacturer in. Illinois. Brick Type. Read More

In India, the enduse sectors of coal mainly include electricity, iron and steel and cement. Demand from the unorganised small scale sector comprising primarily of the brick and ceramic industry is relatively large though infirm as users switch between coal, firewood and biomass depending on

Fire clay for Making Fire Bricks. Fire clay is used to make fire bricks and is generally found under the coal seams. Fire clay contains two major constituents silica and alumina, of which, the silica percentage varies from 60 to 70% and alumina varies from 25 to 35%.

#0183;#32;How Bricks Are Categorized . There are a number of ways that brick can be categorized. For example, you can divide brick into the types used for facing (exposed and visible on the exterior of a structure) vs. backing bricks (which are used structurally and are hidden from view).Another means of categorizing brick is according to how they are manufactured: unfired (brick that is aircured) and

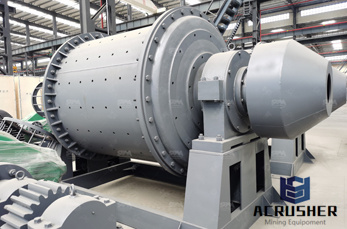

Types of coal for brick manufacturing Coking Coal or Metallurgical coal is used in manufacturing steel, where carbon . like cement, fertilizer, glass, ceramic, paper, chemical and brick manufacturing. . content of all types of coals, which also include bituminous coal and lignite.

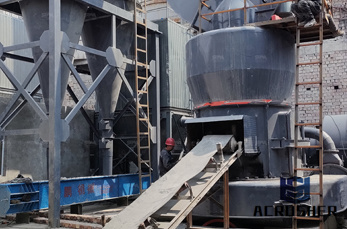

Process flowchart for machine molded brick industry. Energy Use. Nepalese brick kilns use mainly coal as energy resource which is imported from Assam in India. Apart from coal, a small fraction of sawdust/firewood is also used as fuel in these kilns. Brick making is . High Performance Bricks from Fly Ash. Bricks whose solid ingredient is fly

Large amounts of energy are required to produce cement. It takes about 200 kg of coal to produce one tonne of cement and about 300400 kg of cement is needed to produce one cubic metre of concrete. Coal combustion products (CCPs), such as Fly Ash also play an important role in cement manufacture and in the construction industry generally.

The coal formation process involves the burial of peat, which is made of partly decayed plant materials, deep underground. The heat and pressure of burial alters the texture and increases the carbon content of the peat, which transforms it into coal, a type of sedimentary rock. This process takes millions of years. Types, or ranks, of coal are determined by carbon content.

ADVERTISEMENTS: Coal: Types and Uses of Coal! Coal is a black or brown rock, consisting mainly of carbon, which is formed by the compressed vegetative remains of past ages. ADVERTISEMENTS: Much of the presentday high quality coals were deposited during carboniferous era,, about 300 million years ago. More recent deposits of Tertiary age are []

Some of the popular industries which make use of coal are the cement industry, paper and aluminium industry, chemical and pharma industry amongst others. Coal provides numerous raw materials like benozle, coal tar, sulphate of ammonia, creosote, etc. to chemical industries. Coal is mostly used as a source of energy is most of the industries

The brick and structural clay products industry is made up primarily of facilities that manufacture structural brick from clay, For most types of brick, the entire drying, firing, and with coalfired kilns typically use a lowsulfur, lowash coal to minimize SO 2 and PM emissions.

Coal types: Lowrank coals Lignite is the youngest type of coal deposit. It is soft and ranges in color from black to shades of brown. As a result, lignite coal is sometimes called brown coal.

There are four major types (or ranks) of coal. Rank refers to steps in a slow, natural process called coalification, during which buried plant matter changes into an ever denser, drier, more carbon rich, and harder material. The four ranks are:

In turn, the production of hard coal comprised billion tonnes of steam coal and billon tonnes of coking coal. Since the turn of the new millennium, from 2000 to 2014, coal use has grown more strongly than any other primary energy source, by Gtce in absolute terms, helping to meet a Gtce or 36% growth in overall energy demand ( World Energy Outlook 2016, IEA, amp; 64).

designs and more advanced mechanization have all contributed to advancing the brick industry. Other Technical Notes in this series address the classification and selection of brick considering the use, exposure and required durability of the finished brickwork. RAW MATERIALS . Clay is one of the most abundant natural mineral materials on earth.

Uses of Coal Industrial and Domestic Uses of Coal

Coal types: Hard coals Bituminious coal is harder and blacker than lignite and subbituminous coal, and can be divided into two types: thermal and metallurgical. Together, they make up 52 percent of the worlds coal reserves. This coal type is mostly used for power generation, cement manufacturing and other industrial purposes, while

Normally Tailing coal is used for baking bricks. Tailing coal is one of the by product of Coal Flotation process. In the flotation process mm size of coal is processed in the froth flotation cells. Coal slurry is conditioned with collecto...

WhatsApp)

WhatsApp)