Performance Evaluation of Vertical Roller Mill in

In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg. Samples were collected from mill inside and around the circuit to evaluate the

WhatsApp)

WhatsApp)

In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg. Samples were collected from mill inside and around the circuit to evaluate the

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc. Application : Cement Plant, Cl

#0183;#32;VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300350 TPH) and before implementing the project, we would like to

PFEIFFER AG received a contract from Kiasar Cement Industrial Co. to supply a raw mill for the new cement plant at Kiasar in the province of Mazandaran. Apart from the mill, the order covers the feed lock, a vibration conveyor and a bucket elevator for the external material circulation system, the cyclone collector with rotary locks as well as various equipment parts for the gas routes.

A raw mill is the equipment used to grind raw materials into quot;rawmixquot; during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill. The raw milling stage of the process effectively defines the chemistry of the finished cement, and has a large effect upon the efficiency of the whole manufacturing process.

Recently, the vertical roller mill having great grinding performance is widely applied to the raw material grinding process. However, tube mill, which has about 30% poor grinding performance as power consumption, has been still used many existing cement plant. The improvement of this tube mill grinding system is highly expected.

Raw Mill In Cement Plant Cement Making Plant This paper mainly introduces the raw mill in cement plant. In order to achieve the desired setting qualities in the finished product a quantity (28 but typically 5 ) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder.

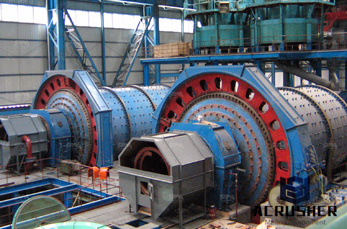

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Vertical Raw Mill | Cement Raw Mill | Raw Mill In Cement Plant. Vertical Roller Mill In Cement Industry Grinding mill in cement industry,grinding machine. in our country, the promotion and use of vertical grinding mill seems a bit slow due to the use of habit, ball mill, roller press as the traditional ball mill grinding equipment, which has more than 100 years of history

In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg. Samples were collected from mill inside and around the circuit to evaluate the

raw material vertical roller mill performance advantage: power consumption, raw material mill system for general 17~20 kWh/t, compared with the tube mill system saves 30% ~ 40%. the operation of the grinding roller and the lining board without direct contact friction, low noise, small abrasion, liner grinding roller, the service life above 6000H

Vertical Roller Mill Used for for Cement Raw Meal in Cement Plant picture from Jiangsu Pengfei Group Co., Ltd. view photo of Vertical Raw Meal Mill, Vertical Slag Mill Used in The Slag Grinding, Roller Press Used for Pregrinding China Suppliers for More Products and Price.

This cement mill is widely used in the grinding of cement raw meal, slag (GGBS plant), cement clinker, raw coal and other raw materials. It gathers grinding, drying and powder selecting as a whole, with high grinding efficiency and high drying capacity (the maximum handling material moisture is up to 20%).

Vertical Roller Mill In Cement Production Plant. Vertical roller mill in cement production plant. There are forty years of manufacturing history, with three major production bases,over 160 senior R D engineers and 600+ large and medium sized digital processing equipment, The first line technicians and professional after sales service personnel up to 2,300+ and 200+

Vertical roller mill with peak raw, cement and slag grinding performance. Our costsaving Vertical Roller Mill (VRM) exhibits a modern design approach. We continuously improve our solution with the latest updates to enhance grinding performance and overall productivity.

FL has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades. The OK mill has been FLs standard cement VRM since 1993. Since its introduction, the OK mill has proven to be the most efficient cement

13 #0183;#32;Zenith''s raw mill also have small ones, which offer an ideal choice for those cement producers

Vertical Roller Mill Boiler Repair Castolin Eutectic. Vertical Roller Mill Repair We can extend the lifetime of VRMs by as much as 100 In the 70s vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their

WhatsApp)

WhatsApp)