Best 30 Concrete Recycling in Plant City, FL with Reviews

Concrete Recycling in Plant City on See reviews, photos, directions, phone numbers and more for the best Concrete Aggregates in Plant City, FL.

WhatsApp)

WhatsApp)

Concrete Recycling in Plant City on See reviews, photos, directions, phone numbers and more for the best Concrete Aggregates in Plant City, FL.

Bowman Asphalt, Inc. offers convenient asphalt and concrete recycling services at our Bakersfield and Ridgecrest asphalt plants. Over the years we have crushed hundreds of thousands of tons of old demolition material for local contractors and paving companies throughout Kern County. After crushing the reclaimed asphalt, aggregate, and concrete, we then screen it to remove any impurities, and use it

Concrete Recycling Station. BIBKO 20m3/h Still working. Brand; BIBKO Allows the separation of the residual concrete s of the mixtrucks with the aggregates in one side and the fines in the other side (cement

Nearly all cement plants have received permits from their local regulators to coprocess these waste derived materials. The infrastructure built at the cement plants to handle these imports from Germany, and the experience of operating the cement kilns with these alternative materials, were accelerating factors in Poland''s recent developments.

Concrete Recycling Machine, Find Complete Details about Concrete Recycling Machine,Buy Concrete Recycling Machine,Concrete Washing Machine,Concrete Recycling Plant Product On from Supplier or ManufacturerQingdao CONELE Group Co., Ltd.

Results for concrete recycling equipment from SprayCannon, Hartl, BIBKO and other leading brands for waste and recycling. Compare and contact a supplier near you

Concrete Recycling Plant Solution. The recycling plant is a highly flexible solution. It is ideal for working in an urban environment and in places with limited space. It is also fast and easy to erect and make ready for production. All you have to do is connect electricity and water, and fill cement in the cement

This project aims to use concrete in a circulair way. They reclaim the old concrete from buildings and put it into this mobile concrete recycling plant, whic...

Jul 01, 2006#0183;#32;Cement plants in North America and countries around the world are increasingly participating in such opportunities. For example, millions of scrap tires are used for fuel every year in cement kilns. Its worth mentioning up front that a huge benefit of cement kilns is that the cost of standalone wastetoenergy incinerators is avoided.

Mar 25, 2020#0183;#32;Additionally, there are also extra processes that are done before recycling the cement. They remove specific particles that may contaminate the recyclable material using pieces of equipment such as magnets, separators, and the like. According to Wikipedia, recycling cement/concrete saves up to 1,360 gallons of water and 900 kg of carbon dioxide.

Renton Concrete Recyclers was established in 1988 as a cost effective, environmentally sound way to deal with concrete and asphalt demolition materials. We process concrete and asphalt material into

The Recycling Center. The Recycling Center accepts concrete, asphalt, brick, block, and related materials. We then recycle the raw material into a finished product that can be used as an economical substitute for aggregates.

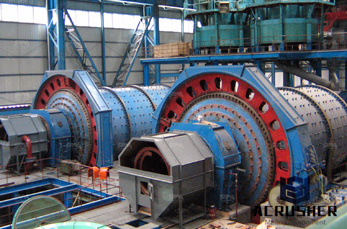

ELKON Concrete Recycling Plant consists of a concrete discharge bin equipped with a shower system for washing waste concrete, a recycling unit separating coarse aggregates from the mixture and a pool where waste water discharges into. There is also an agitator which prevents the cement particles from sinking in the pool where the recycled water

Recycles concrete, asphalt, rubber tires and wood in Denver, Colorado.

278 cement recycling plant products are offered for sale by suppliers on, of which paper product making machinery accounts for 1%, recycle washing line accounts for 1%, and other rubber processing machinery accounts for 1%. A wide variety of cement recycling plant

Fresh concrete recycling system. Managing the fresh concrete leftovers in the truck mixers and concrete pumps, as well as in the plants mixer, is a daily problem that readymix concrete industries have to cope with. Beyond the environmental aspect and the obligations arising from legislation, an equally important issue is the economical one.

Home / Products / Concrete Recycling Plants / Filterpress Water Recycling System. Introducing our new Filterpress Water Recycling System. The filterpress is designed for cement waste water clarification. Simple compact system. Produces clean water for reuse in concrete manufacture.

CONCRETE RECYCLING PLANT. ELKON Concrete Recycling Plants provide a cost saving advantage for its users by recycling concrete components as well as protecting the environment. Since the Concrete Recycling Plant can be installed next to concrete batching plants, the cost of transporting the residual concrete

WhatsApp)

WhatsApp)