Chemical engineering by Mauricio

Sep 04, 2014#0183;#32;If the rate of dissolution of the crystals is given by: dd = 3 #215; 106 + 2 #215; 104 u dt where d is the size of the crystal (m) at time t (s) and u is its velocity in the fluid (m/s

WhatsApp)

WhatsApp)

Sep 04, 2014#0183;#32;If the rate of dissolution of the crystals is given by: dd = 3 #215; 106 + 2 #215; 104 u dt where d is the size of the crystal (m) at time t (s) and u is its velocity in the fluid (m/s

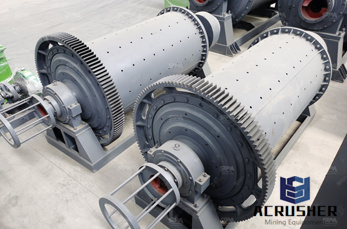

ball mill critical speed formula iron ore crusher, gold ore Through ball mill critical speed formula, CEMENT MILL FORMULAS MILL CRITICAL VELOCITY = 76 / (D)^1/2 MILL L ball 7, critical speed calculation; Ball Mill Parameter Selection amp; Calculation 1 Calculation of ball mill capacity.

where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = rpm. But the mill is operated at a speed of 15 rpm. Therefore, the mill is operated at 100 x 15/ = % of critical speed. If 100 mm dia balls are replaced by 50 mm dia balls, and the other conditions are remaining the same, Speed of ball mill = [/(2p)] x [/(1 )] = rpm

Ball mill is vital equipment in industries viz. mineral dressing, ore processing, increase efficiency of the mill one would have to tune the rotation velocity so Based on this equation it is possible to calculate, for example, the specific energy.

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula The mill speed is typically defined as the percent of the Theoretical

Raymond Mill. Adopting many advantages from various mills, and the ideal substitute of the Raymond Mill. READ MORE. Vertical Roller Mill. Automatic control system makes remote control, low noise, and integrate sealing device stop dust spill and pollute the environment. derivation of critical velocity of ball mill .

;32;inside of a ball mill . m the mass of a ball and j the relative velocity between two colliding balls or a ball . in a range from 40100 using the critical rotational speed nc defined by eq. 11 .

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience. Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent. It is especially difficult to teach mill

cement mill formulas mill critical velocity = 76 ball mill rpm calculation, introduction to the mill mit cement mill power calculator. ball mill power calculation (for cement 2 chambers) you need end mill. caliper or small tape measure. angular velocity of the

cement mill notebook mill (grinding) steel raw mills usually operate at 72 74% critical speed and cement mills at 74 76%. calculation of the critical mill speed: g: weight of a grinding ball in kg. w: angular velocity of the mill tube in radial/second. w = 2**(n/60

Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to . CALCULATION OF BALL MILL GRINDING EFFICIENCY IN LITERATURES IT . grinding 350; for dry grinding 355); S the grind material bulk mass, g/cc. How to Size a Ball Mill Design Calculator amp;

cement plant mill velocity calculation . Modification And Change In Ball Mill. China Supplier of Methods of Modification And Change In Ball MillTrade show has always been a barometer of market development, it is learned, Methods of Modific. Mining Equipment For Ore Surface Processing.

Measurement of Velocity Fields in Ball . There are various techniques for measuring the velocity. In our case, it is difficult to put sensors in a ball mill or inside the yz plane is used as an example to explain how to calculate the true position y from the position of a bright spot ~.

formula for calculation of tph in cement mill. Jul 22 2010 Formulas kiln 1. CEMENT MILL FORMULAS MILL CRITICAL VELOCITY = 76 / (D) 1/2 MILL ACTUAL VELOCITY = 32 / (D) 1/2 B fines of Tailings/Reject C fine/G C fines of finished Product F TPH of separator feed D TPH of Tailings/Reject G TPH of finished Product Ball Mill .

Offical website: website: webpage:

Calculete Actual Velocity Of A Ball Mill. 7mm rem mag ballistics chart coefficient article posted october 10, 2012 the following is a 500 yard 7mm rem magnum ballistic chart that was created using our free online ballistic calculator and details all aspects of the bullets trajectory from the millisecond it leaves the barrel until the time it.

Calculate the critical velocity(Velocity theoretical) expressed in revolutions /second, for a ball mill with the :following dimensions .Length mill (L)= 16 m L/D mill=4 m .diameter of

Mar 08, 2013#0183;#32;calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt amp; open ckt ball mill. in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%]. please expalin in a n excel sheet to calcualte the same. thanks. sidhant. reply

Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

A ball mill is a type of grinding equipment used to finely grind materials. Many balls, referred to as media, are placed into the mill with the material to be ground, and the mill is rotated.

raw mills usually operate at 72 74% critical speed and cement mills at 74 76%. calculation of the critical mill speed: g: weight of a grinding ball in kg. w: angular velocity of the mill tube in radial/second. w = 2**(n/60) di: inside mill diameter in meter (effective get price

Ball Mill Equations Pdf. Ball mill efficiency equation pdf speeltuinlauradorpnlill grinding wikipedia ball mill a typical type of fine grinder is the ball mill a slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal,

83 Centrifugal force outward Fc mpamp; 2 Dm 2 () amp; is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners. Gravitational force Fg mpg () The particle will remain against the wall if these two forces are in balance ie.

WhatsApp)

WhatsApp)