vertical roller cement mill working principle

Vertical roller mill WikipediaSummaryOverviewOperationPrincipleMethod of operationBenefits over ball millLimitationsVertical roller mill is a kind of grinding m

WhatsApp)

WhatsApp)

Vertical roller mill WikipediaSummaryOverviewOperationPrincipleMethod of operationBenefits over ball millLimitationsVertical roller mill is a kind of grinding m

Design and Realization Of Roller Mill Control System . Jan, cement raw materials from the analysis of vertical roller mill control points for the control area in terms of vertical mill automatic control system is designed to ensure stable operation of the vertical mill under the condition that the load is increased to achieve the best vertical mill

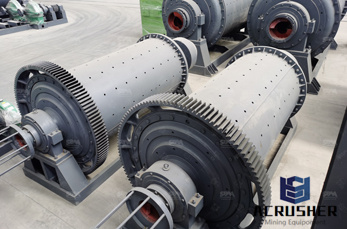

Vertical roller mills Vs ball mills has long been a raging debate in the cement industry. In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated

Design and Realization Of Roller Mill Control System . Jan, cement raw materials from the analysis of vertical roller mill control points for the control area in terms of vertical mill automatic control system is designed to ensure stable operation of the vertical mill under the condition that the load is increased to achieve the best vertical mill product output, quality, and reduce the energy

Vertical coal grinding mill integrates crushing, drying, grinding, powder selection and conveying.; It has simple system and compact structure. Vertical coal mill covers an floor area about 50% of the coal ball mill with the same specification.; Coal vertical mills can work in openair environments, greatly reducing the cost of investment. The design of the vertical coal mill system is simple

Mar 13, 2019#183; Thailand: Siam Cement has ordered a LM +3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi. The mill will produce mediumfine cement qualities and is designed for grinding clinker, gypsum and limestone. The cement producer previously ordered a LM +3 CS mill from Loesche for its Ta Luang cement plant in 2014. Grinding Mill Machine in Cement About Us

Jul 24, 2019#0183;#32;Bangladesh: The largest ever vertical roller mill in Bangladesh''s cement industry, owned by Bashundhara Group (BG), was inaugurated on Monday 12 November 2012 at a ceremony in Khulna. Mayor of Khulna, Talukdar Abdul Khaleque, along with managing director of Bashundhara

India/Germany: ACC has ordered two vertical roller mills from Loesche, in a consortium with KHD, for its Jamul cement plant. The Holcim subsidiary has ordered a Loesche Mill Type LM +3 CS equipped with a classifier type LDC to grind clinker. The vertical roller mill will be operated with the power of a 5600kW motor and will have a capacity of 195t/hr.

Vertical coal grinding mill integrates crushing, drying, grinding, powder selection and conveying.; It has simple system and compact structure. Vertical coal mill covers an floor area about 50% of the coal ball mill with the same specification.; Coal vertical mills can work in openair environments, greatly reducing the cost of investment. The design of the vertical coal mill

vertical roller mill of bashandhara . Second Hand Concrete Batching Plants For Sale In Malaysia. Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete

The higher the feeding material moisture content, the more energy the machine can save. The grinding mill has high drying capacity, as it uses the hot waste gas from the cement kiln for material drying. Vertical Mill Our and PRM types of vertical mill are designed with both grinding wheel and grinding rollers. The rollers press with high pressure against the rotating grinding wheel, so as to grind the

Raymond Mill. Adopting many advantages from various mills, and the ideal substitute of the Raymond Mill Vertical Roller Mill. Automatic control system makes remote control, low noise, and integrate sealing device stop dust spill and pollute the environment. READ MORE. Sand Making Machine. how much loesche cement mill vrm .

types of grinding mills in cement industry. cement mill/raw material mill. wear plate for cement industry. cement mill feed hoppers india. project report of mini cement crusher plant. heat transfer calculation of cement mills. mobile cement production equipment. vertical roller mills for bashundhara cement. mini milling machine for grinding cement

Nov 03, 2016#0183;#32;FL OK Mill, Vertical Roller Mill For Cement Grinding.

Bangladesh: The largest ever vertical roller mill in Bangladesh''s cement industry, owned by Bashundhara Group (BG), was inaugurated on Monday 12 November 2012 at a ceremony in Khulna. Mayor of Khulna, Talukdar Abdul Khaleque, along with managing director of Bashundhara Group Sayem Sobhan and other guests inaugurated the factory.

Nov 12, 2012#0183;#32;In 1996 Bashundhara group entered into cement production industry. Then the cement production capacity was three lakh tones annually. In 1998 the capacity enhanced to 7 lakh 20 thousand tones in the expanded project. So long the cement in the country was produced in Ball mills. Though there were few vertical mills those were small.

Vertical Roller Mill Of Bashandhara. Vertical roller mills for bashundhara cement vertical roller mill for cement pictures cement mill wikipedia a cement mill or finish mill in north american usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also Read More Corundum Stone Mill

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics. It is an energy efficient alternative for a ball mill.

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, our vertical roller mill solution for cement

Bangladesh: The largest ever vertical roller mill in Bangladesh''s cement industry, owned by Bashundhara Group (BG), was inaugurated on Monday 12 November 2012 at a t/h Coal Mill for Jenakievo/Ukraine another

Bashundhara Industrial Headquarter 1. Plot# 3, Block# G, Umme Kulsum Road, Bashundhara R/A, Dhaka1229 +880 2 .

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, our vertical roller mill solution for cement grinding

vertical roller mill in cement industry dewirix be. Vertical roller mill in cement industry mainly consisted of the separator, roller, disc, pressure device, reduce, motor, shell and other components roller compacted cement material for grinding is the main components vertical roller mill in cement industry built with two pairs of rollers, each roller

WhatsApp)

WhatsApp)