Simulating the Bond rod mill grindability test | Request PDF

The Work Index is used when determining the size of the mill and grinding power required to produce the required ore throughput in a ball mill [Bond 1961].

WhatsApp)

WhatsApp)

The Work Index is used when determining the size of the mill and grinding power required to produce the required ore throughput in a ball mill [Bond 1961].

Jul 30, 2020#0183;#32;An improved method using less mass compared to the Bond Ball Mill Work Index test The JK Bond Ball Mill (JKBBM) test, is a locked cycle grindability test conducted using a standard laboratory Bond Ball Mill with the same steel ball charge and material feed size ( passing mm) as the Bond Ball Mill Work Index test.

The Bond work index is a measure of ore resistance to crushing and grinding and is determined using the Bond grindability test. Its value constitutes ore characteristic and is used for industrial

According to the Bond standard procedure, the work index is determined by simulating a dry grinding in a closed circuit in the Bond ball mill to achieve 250% circulating load (Bond, 1949, 1952, 1961). The test is performed on a raw material approximately weighing 10 kg, which coarseness is mm.

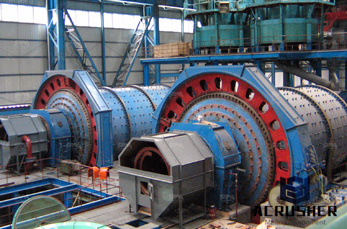

Bond Ball Mill Grindability Test. The Bond Ball Mill Work Index (BBWi) test is carried out in a standardised ball mill with a predefined media and ore charge. The Work Index calculated from the testing can be used in the design and analysis of ball mill circuits. The test requires a minimum of 10kg of sample that has been stagecrushed to passing size of lt; mm.

bond method for ball mill work index test The grinding jar for the Bond Index Rod Mill is 12 x 24 in size and has a waveshaped design At least 15 to 20 kg sample material is required to simulate a closed grinding circuit in a ball or rod mill The Rod Mill Work Index RWI is used for particle size determination in a size range from 25 mm down to 21 mm whereas Ball Mill Work

Abstract: The standard Bond method is the most acceptable method for designing and selecting ball/rod mills described by their basic parameter called work index (W i). The standard Bond method is a tedious time consuming procedure requiring at least 7 10 grinding cycles, so that many researchers have tried to

The Bond ball mill grindability test is run in a laboratory until a circulating load of 250% is developed. It provides the Bond Ball Mill Work Index which expresses the resistance of material to ball milling. This happens after 710 grinding cycles, which shows that the procedure is a lengthy and complex one and is therefore susceptible to procedural errors.

It is commonly known that one must run the Bond ball mill work index test such you pick a closing mesh to give a P80 close to desired grind size. This is because work index frequently changes as a function of the product size in comminution. If target grind size during a project is changed, or if

Here is the old AllisChalmers Bond Work Index Grindability Test Procedure. The standard feed is prepared by stage crushing to all passing a 6 mesh sieve, but finer feed can be used when necessary. It is screen analyzed and packed by shaking in a 1000cc graduated cylinder, and the weight of 700 cc is placed in the mill and ground dry at 250 per cent circulating load. The mill is 12 in. x 12

Test WI of circuit feed ore = kWh/t (The Bond ball mill test Work Index of the ore, whichapplies over the size reduction range of this circuit) W = 3,150 kW / 450 t/h = kWh/t. WIoACT = / (10/ 212 10/ 2,500) = kWh/t. The circuits Bond WI Ratio Eff. = / =, or 112%.

The Bond Abrasion Test determines the Abrasion Index, which is used to determine steel media and liner wear in crushers, rod mills, and ball mills. Bond developed the following correlations based on the wear rate in pounds of metal wear/kWh of energy used in the comminution process. Wet rod mill. Rods.

This study aims to develop a new approach toward estimating the Bond ball mill work index (BBWI) by applying a series of kinetic grinding tests with Bond standard mill.

The Bond ball mill work index is one of the most commonly used grindability tests in mining, and is often referred to as the Bond work index. The test is a ''lockedcycle'' test where ground product is removed from test cycles and replaced by fresh feed. The test much achieve a

This knowledge is essential to define the required ball mill layout and production capacity. In order to perform the Bond Index Test successfully it is necessary to use precrushed sample material as defined below: Module Ball Mill. Minerals precrushed to lt; mm and sieved ; Drillcore precrushed to lt; mm and sieved ; Half Drillcore precrushed to lt; mm and sieved ; The Bond Index conforming ball

Bond Work Index Tests. Bond ball mill grindability bond ball mill work index (bbwi) test is carried out in a standardised ball mill with a predefined media and ore work index calculated from the testing can be used in the design and analysis of ball mill test requires a minimum of 10kg of sample that has been stagecrushed to .

Bond Ball Mill Grindability Test. The test determines the Bond Ball Mill Work Index which is used with Bonds Third Theory of Comminution to calculate net power requirements*. Various correction factors may have to be applied. W = Wi (10/P 10/F) Where W = Net power consumption in kWh/t Wi = Bond work index (either Imperial or Metric units)

A Bond Ball Mill, 12 x 12 of fabricated construction comes with electric motor and gear reducer drive, digital counter, jogging button to provide positioning of drum for loading and unloading, emergency stop button, 44 #189; lb ball charge, stand and receiving pan. Perform Fred C. Bond''s grindability tests with this standard BWi test ball mill.

Bond Work Index Test Ball Mill. US 13,800. The FC Bond Work Index Test Ball Mill was designed by F. C. Bond for use in determining the Bond Index, a measure of grindability and power required for grinding applications. The FC Bond Mills are used in laboratories throughout the world. A copy of Fred C. Bonds Method of Crushing and Grinding for determination of the Bond Index is included with

A Bond Ball Mill Work Index test is a standard test for determining the ball mill work index of a sample of ore. It was developed by Fred Bond in 1952 and modified in 1961 (JKMRC CO., 2006).This index is widely used in the mineral industry for comparing the resistance of different materials to ball milling, for estimating the energy required

The ball mill work index laboratory test is conducted by grinding an ore sample prepared to passing mm (6 mesh) to product size in the range of 45150 #181;m (325100 mesh), thus determining the ball mill work index (Wi B or BWi). The work index calculations across a narrow size range are conducted using the appropriate laboratory work index determination for the material size of

This Grindability Test or Bond Ball Mill Work Index Procedure is used to determine the Bond Work Index of minus six mesh or finer feed ore samples. These equation application methods are used to process lt;1/2 ore samples in a Ball Mill using a standard ball charge. Below describes in general terms the Bond Work Index Procedure used by a Professional Metallurgical Testing Laboratory. If you

WiBM Bond Ball Mill Test Work Index (kWh/t) Wic Bond Impact Crushing Test Work Index (kWh/t) WioACT Actual Operating Bond Work Index determined from measurements on the circuit (kWh/t) WiRM Bond Rod Mill Test Work Index (kWh/t) WiSTD Standard Circuit Bond Work Index (expected or designed) used for circuit design. Specific energy requirement at the drive pinions.

WhatsApp)

WhatsApp)