Why Molybdenum Is an Essential Nutrient

May 06, 2017#0183;#32;Molybdenum is an essential mineral in the body, just like iron and magnesium. It is present in soil and transferred into your diet when you consume plants,

WhatsApp)

WhatsApp)

May 06, 2017#0183;#32;Molybdenum is an essential mineral in the body, just like iron and magnesium. It is present in soil and transferred into your diet when you consume plants,

Roughly 40 percent of molybdenum comes from primary mines, with the other 60 percent a byproduct of copper or, in some cases, tungsten. If the ore lies close to the surface, openpit technology will be used, and if the ore lies deep underground, the underground method will be used. Processing. Flotation.

Mineral and Ore Processing Surveys Merrett Mining Surveys. Our 3D modelling and BIM modelling services can have a big impact in terms of the final result in your mineral processing project, at both the plant design and operational stages. Clash detection is a particularly valuable tool when designing plant modifications or improvements.

mining and minerals processing industries under reference 203 F8 Estimated longrun effects of a 25 per cent reduction in 1987 levels of agricultural assistance 205 H1 Average nominal rates on outputs for selected mineral processing activities, 198384 to 198990 and mid1990s 226

Molybdenum mining in the United States produced 65,500 metric tons of molybdenum in 2014, worth US billion. The US was the world''s secondlargest molybdenum producer, after China, and provided 25% of the world''s supply of molybdenum.

Molybdenum mining process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design. read more.

Thompson, P, Baum, W, Zn, R and Yu, S, 2014. Coppermolybdenum concentrator surveys using mineralogy and process benchmarking tools to improve overall plant performance, in Proceedings 12th AusIMM Mill Operators Conference 2014, pp 315322 (The Australasian Institute of Mining and Metallurgy: Melbourne).

Molybdenum (Mo) is a refractory metallic element used principally as an alloying agent in steel, cast iron, and superalloys to enhance hardenability, strength, toughness, and wear and corrosion resistance. To achieve desired metallurgical properties, molybdenum, primarily in the form of molybdic oxide or ferromolybdenum, is frequently used in combination with or added to

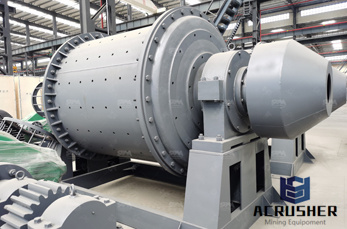

This Molybdenum Mineral Processing Plant shows a flotation craft to process Molybdenum. The stone goes through crushing, grinding, classifying, flotation, dewatering and etc.

The majority of the world''s moly supply flows from two distinct types of mining operations: as a byproduct typically of copper mining (in Canada, Chile, Peru and the ) amounting to around

The Questa Molybdenum Mine is a surface and underground mining operation. Initial production took place in 1923 and overall output was considered to be large size. Mine operations consist of 2 distinct surface and underground workings extending hectares ( acres).

Molybdenum dressing production line is useds to extract molybdenum from raw ores. Case Study: A Gold Processing Plant Process Transformation and Upgrade. Mining plant 2 cubic remote control scraper efficient recovery of residual ore.

The life cycle of mining begins with exploration, continues through production, and ends with closure and postmining land use. New technologies can benefit the mining industry and consumers in all stages of this life cycle. This report does not include downstream processing, such as smelting of

Molybdenum processing plant ore processing ore grade higher ( to ), enrichment ratio of 133 to 155, its original design featured a total number of 7 times, Jinduicheng processing plant molybdenum processed raw ore grade of approximately , the enrichment ratio of 430 to 520, and advice total number of up to 12 times.

Molybdenum mining amp; processing. Molybdenum mining and processing techniques have been improved continuously since the first mine was started at Climax near Leadville, Colorado in 1916. Today, the principal moly mines, both primary and byproduct, are found along the Great Continental Divide of the Americas, in China and in the CIS. Many of these mines are amongst the most

Processing Plant Flowsheet Design For mining clients, these services cross the project life cycle from earlystage exploration through development and operations to closure. Mineral Exploration Mineral Exploration Add value to your project by using the latest exploration techniques and innovative technologies to design and implement your

The Mining Process. Montana Resources operates an open pit copper and molybdenum mine in Butte, Montana. The operation comprises the Continental mine, crushers, and a concentrator facility where tons of raw ore are processed into highquality metal concentrates. We serve an international market for these important metals. Uses of Molybdenum and

Dec 18, 2017#0183;#32;Opinion mining is considered as a subfield of natural language processing, information retrieval and text mining. Opinion mining is the process of extracting human thoughts and perceptions from unstructured texts, which with regard to the emergence of online social media and mass volume of users comments, has become to a useful, attractive and also challenging issue.

Molybdenum mining and processing techniques have been improved continuously since the first mine was started at Climax near Leadville, Colorado in, the principal moly mines, both primary and byproduct, are found along the Great Continental Divide of the Americas, in China and in the CIS. Many of these mines are amongst the most productive in the world, with the largest capable of moving over

The Fort Madison Conversion Molybdenum Plant is a processing plant. The Dissected Till Plains of the Interior Plains characterize the geomorphology of the surrounding area. Site identification and general characteristics. Public Land Survey System, and mining claims.

Wikizero Ore Molybdenum Mining And Ore Processing Plant Equatorial Guinea. Ore is natural rock or sediment that contains one or more valuable minerals typically metals that can be mined treated and sold at a is extracted from the earth through mining and treated or refined often via smelting to extract the valuable metals or minerals..

Sep 05, 2019#0183;#32;Molybdenum is a silverwhite metal with an atomic number of 42, a density of g / cm#179;, a melting point of 2610 #176; C, and a boiling point of 5560 #176; C. Molybdenum mining and processing technology have been improving since 1916, when Climax molybdenum

WhatsApp)

WhatsApp)