ball mill risk assessment

Serious crush injuries caused by falling ball Know More. 23 Oct 2013 still in place inside the ball mill when the top liner plate was dislodged and fell, Mill relining tasks should include a pretask

WhatsApp)

WhatsApp)

Serious crush injuries caused by falling ball Know More. 23 Oct 2013 still in place inside the ball mill when the top liner plate was dislodged and fell, Mill relining tasks should include a pretask

Ball mills are allrounders and together with their broad range of accessories they allow dry, wet, and even cryogenic grinding in one instrument. Especially for elastic samples ( plastics) and instable samples such as materials which contain volatile components, cryogenic grinding ensures a homogeneous final sample which provides the best recovery rates, even for subsequent quantitative

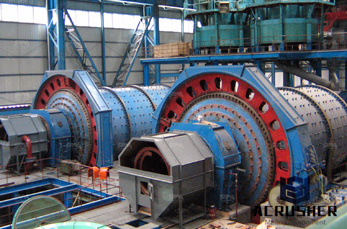

4/7/2020#0183;#32;A ball mill is one of the most commonly used grinding machines in many industries. The material is crushed by the balls which are embedded in a container or a compartment. This type of grinder is also used for mixing and blending materials for paints, ceramics and pyrotechnics etc.

Ball mill working principle High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits. Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, the manganese, iron, steel balls or ceramic are used

Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles with quality workmanship and materials used in the construction of the component parts. Your Ball Mill reflects years of advancement in grinding principles, materials, and

Ball mill 1012 is located in line 3 of the mines production circuit and had the potential and capacity to process more material if some modifications were made. Colluasi decided to award the project of repowering this mill to , given the previous positive experience and years the two companies had worked the mining company''s overall strategy, increasing its production

has made in ball mill circuit design is due to the historic success of Bonds method [1] in crusherball mill and rod millball mill circuits. Unfortunately Bonds method is limited to providing the required mill power draw for a given duty. In doing so it relies on certain assumptions, including the shape of

a diverse ball mill mill for serious tasks; Lets Get Started with MINIGN Now Get Price. Request a Call Back. The diameter of the balls is between one and several centimetres to suit the application smaller balls for fine milling results and larger ones for coarser milling tasks.

The overpressurization of a laboratory ball mill reactor designed for operation under slightly elevated pressures resulted in a serious injury. The apparatus had been routinely operated under argon and hydrogen pressures of 510 atmospheres for nearly two years. The apparatus had not been tested for operation at pressures greater than 10 atm.

30/1/2018#0183;#32;Ball mill working principle High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits. Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, the manganese, iron, steel

Ball temperature as a function of milling time when using a SPEX mill and flatended vial with five balls and no powder (D). The continuous line represents a fitted exponential.

Brief Introduction of Ball Mill: Ball Mill are giant drums that are filled to between 30 and 40% of their volume with freely moving grinding media in this case balls. The diameter of the balls is between one and several centimetres to suit the application smaller balls for fine milling results and larger ones for coarser milling tasks.

The relining of SAG mills, ball mills, verti mills, grinding mills and scrubbers are our specialty. Our teams have extensive experience servicing all types of mills and lining systems and are able to undertake backing rubber and shell repairs. We are equipped with a selfcontained diesel driven 40,000 psi D115 Ultra OSS Water laster for all

23/9/2014#0183;#32;Most of our work since 2000 has been in developing grinding mill foundations to avoid vibration and unacceptable deflections. On a recent project for a plant in Peru, the client was told by the mill vendor that there was no need to do a systems (dynamic) analysis on the mill foundations because the mills on that project were gear driven rather than being driven by ring motors (gearless drives).

Potential for serious injury from uncontrolled rotation of rotary kiln dryer . SIR 207. Serious crush injuries caused by falling ballmill liner plate . SIR 187. A contractors legs were crushed between the arm and pinch points of an indexer (used to move train carts along train line). The incident occurred during a threeday maintenance

Product Details: Voltage. 220V380V. Power. Speed. Upto 70rpm. Work Index Ball Mill, alluding to the grind ability list of Metals, is utilized to demonstrate the granulating trouble of the material. It is measured by a rule that to compute the work file ball plant in light of yield of every unrest of the factory after the material is ground

In 2013 a maintenance worker was seriously injured during a ballmill relining operation at a Western Australian mine when he was struck by a large liner plate weighing about tonnes. At the time of the incident, the worker had been preparing to remove two unsecured liner plates still in place inside the ball mill when the top liner plate was dislodged and fell, pinning him to the ground.

Ball mills are giant drums that are filled to between 30 and 40% of their volume with freely moving grinding media in this case balls. The diameter of the balls is between one and several centimetres to suit the application smaller balls for fine milling results and larger ones for coarser milling tasks.

CONSTRUCTION. CMI Technical Services reputation has been built from its ability to deliver Ball Mill installations with a high degree of quality that ensures the Mills consistent availability during key ore commissioning phases, thus ensuring a solid move into commercial production

order to fulfill all the above tasks a ball mill automation and optimization system was developed (see Fig. 3). 3. DESCRIPTION OF THE DEVELOPED BALL MILL AUTOMATION SYSTEM . The structural diagram of the developed ball mill automation and optimization system is shown on Fig. 4. A piezoceramic accelerometer is mounted on the front bearing

WhatsApp)

WhatsApp)