Quality Vertical Cement Mill amp; Cement Ball Mill factory

Raw Coal Vertical Roller Mill Cement, High Performance Vrm Cement Mill Contact Now 90t Horizontal Coal Grinding Mill, 110kw Wet Ball Mill In Cement Plant

WhatsApp)

WhatsApp)

Raw Coal Vertical Roller Mill Cement, High Performance Vrm Cement Mill Contact Now 90t Horizontal Coal Grinding Mill, 110kw Wet Ball Mill In Cement Plant

Coal Mill in Cement Plant India,Vertical Roller Mill for Vertical Roller Mill for Cement Plant. The material is input onto the turn table through the material input port on top of the vertical roller mill

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc. Application : Cement Plant, Cl

As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise operating costs. The high energy efficiency is especially beneficial in regions with limited power generating capacity or where electricity availability is limited.

Vertical Roller Mill Parts In Cement Plants Crusher Mills, Cone Crusher, Jaw Crushers. optimisation of vertical roller mill in cement plant #187; hardinge 6 x 2 used kopper #187; svedala hydrocone crusher parts manual #187; mclane 20 rp 7 height Vertical roller mill in cement plant is the most widely used Great Wall GGBSamp;Cement Plant,cement grinding

Coal Vertical MillVertical coal mill is typically designed to process materials in medium hardness, like soft coal or bituminous coal, and it is mainly used in positive pressure pulverizing system of soft is widely used in thermal power plant, metallurgy sector, building material industry, chemical industry, etc.

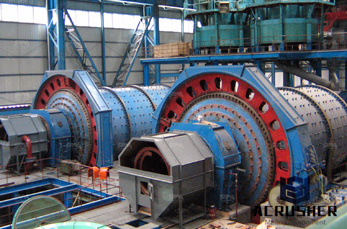

Coal mill is also called coal pulverizer or coal grinder. It is a mechanical device used to grind raw coal into pulverized coal powders. The most used coal mills in cement plants are airswept ball mill and vertical roller mill.. At present, most cement plants use coal

Vertical Roller Mill. Automatic control system makes remote control, low noise, vertical roller mill working in cement plant . Chinaamp;#8217;s coal Conditions and Policiesamp;# General performance Solutions that include Inner Cylinder Magnetic Separator.

Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation

Vertical coal grinding mill integrates crushing, drying, grinding, powder selection and conveying.; It has simple system and compact structure. Vertical coal mill covers an floor area about 50% of the coal ball mill with the same specification.; Coal vertical mills can work in openair environments, greatly reducing the cost of investment. The design of the vertical coal mill

Vertical coal grinding mill integrates crushing, drying, grinding, powder selection and conveying.; It has simple system and compact structure. Vertical coal mill covers an floor area about 50% of the coal ball mill with the same specification.; Coal vertical mills can work in openair environments, greatly reducing the cost of investment. The design of the vertical coal mill system is simple

LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology. Our designers are constantly coming up with new ideas and even more dependable components to reduce the already acclaimed low failure rate of our mills.

WhatsApp)

WhatsApp)