(PDF) Life cycle assessment of iron ore mining and

Mining of iron ore is a highly capital and energyintensive process. Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter

WhatsApp)

WhatsApp)

Mining of iron ore is a highly capital and energyintensive process. Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter

Iron Mining Process. From blasting to crushing to separation more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nations steel. Blasting Taconite is a very hard rock. Using explosives, the taconite is blasted into small pieces. Transportation The taconite pieces are scooped up by electric shovels. Each shovel can hold up to 85 tons of rock

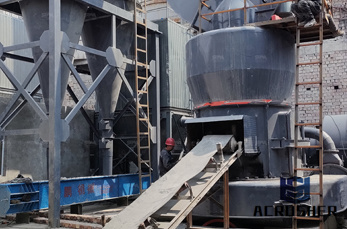

Optimized and integrated mineral processing. To produce the required commodity such as ore concentrates, pellets and DRI/HBI for iron ore, copper cathodes, nickel or zinc ingots as well as alumina, etc, ABB processes not only cover material handling or comminution (crushing and grinding) but also hydrometallurgy (ore beneficiation / concentration and/or SXEW), agglomeration (including

Iron ore mining methods vary by the type of ore being mined. There are four main types of iron ore deposits worked currently, depending on the mineralogy and geology of the ore deposits. These are magnetite, titanomagnetite, massive hematite and pisolitic ironstone deposits. Banded iron formations. rock showing banded iron formation. Processed taconite pellets with reddish

Differences in ore composition and presence of iron, silicon and titanium impurities influence their subsequent processing. 90% of the worlds bauxite reserves are concentrated in tropical and sub tropical regions. Large blanket deposits are found in West Africa, Australia, South America and India as flat layers lying near the surface, extending over an area that can cover many square

;32;mining iron ore mining iron ore . process of separating the iron from the noniron material. the magnetic iron ore is then . a clay from wyoming used to help iron ore concentrate stick together when rolled into

The Ore Extraction and Refining Process Before iron ore can be used in a blast furnace, it must be extracted from the ground and partially refined to remove most of the impurities. Leaning on his long tongs, this young iron puddler''s helper posed for this photograph in the early 1860s, when the Sons of Vulcan was a young union. (From the collections of Henry Ford Museum amp; Greenfield Village

Mining Of Iron Ores Ispatguru . Mar 14 The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent location and.

Ore, which contains an economical use of iron, is called an iron ore. There are many types of iron ore, magnetite (Fe3O4), hematite (Fe2O3) and (FeCO3), etc, which are mainly used for iron making. Iron ore is an important raw material for iron and steel production enterprises. After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural

the mining processing and refining of iron ore. mining iron ore and refining process The Ore Extraction and Refining Process Before iron ore can be used in a blast furnace, it must be extracted from the ground and partially refined to remove most of the impurities.

WhatsApp)

WhatsApp)