leaching gold in manganese ore crusher

A Method for Leaching or Dissolving Gold from Ores orlurgical gold extraction routes utilize a leaching step to produce a goldbearing solution as an inter leaching gold in manganese ore crusher

WhatsApp)

WhatsApp)

A Method for Leaching or Dissolving Gold from Ores orlurgical gold extraction routes utilize a leaching step to produce a goldbearing solution as an inter leaching gold in manganese ore crusher

Heap Leaching A Stack Of Gold Miningfeeds. heap leaching can take anything from a couple of months to several yearsn the case of gold recovery, heap leaching generally requires 60 to 90 days to leach the ore, compared to the 24 hours required by a conventional agitated leach processold recovery is also usually only 70 compared with 90 recovery in an agitated leach plant.

The 700tpd gold vat leaching plant adopt the process: ore crushing and washing + pool leaching absorption + activated carbon acid washing regeneration + smelting. The mainly used machines of the project are hammer crusher, trommel, agent agitation tank, carbon adsorption column, desorption electrolysis system, pickling tank, cone agitation tank

Gold Leaching Carbon In Leach Jxsc Machine. 20206 5Gold Leaching carbon in leach process is widely used in the newly built gold leaching plants in recent years and a lot of plants are changing into CIL as Leaching CIL process is suitable for the treatment of oxidied gold ore with low sulfur content and mud content.

In Leaching for Gold, there is often a tendency to overlook or minimize the importance of the small mine. The small mine of today may develop into the large mine of tomorrow. Under proper management and financing it has as good a chance of yielding a profit as the larger property. Unfortunately large capital is seldom interested in them and they are left to the small groups who are not in a

Pour the acidandbleach mixture into the plastic bowl with the ore grains and stir Allow four hours for the gold to dissolve stirring every 20 minutes The chlorine reacts with the gold inside the ore to form gold chloride Filter the ore and bleach solution to remove all the impurities such as soil and rock fragments...We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone

Leaching Gold and Silver Ores. The Plattner And Kiss Leaching The Gold Ore 96. Leaching The Gold Ore. After the ore is supposed to have remained long enough in contact with chlorine

Gold Mine Heap Leaching Process. Crushed by jaw crushers and cone crushers to a certain particle size (3050mm), raw ore is directly sent for heaping or granulated (to make finer particles agglomerate into coarse powder), and then transported to the ore heap site for heap construction.

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

The evaluation of agitated tank leaching verses CIP and CIL circuits is not as complex as the heap leachagitated tank leach analysis. CIP and CIL circuits generally have lower capital and operating costs for gold ore bodies than agitated tank leach circuits. Silver ore bodies show better economics with agitated tank leachMerrill Crowe circuits.

mining, ore preparation, and stacking mining of ore for heap leaching employs the same techniques and equipment as mining of ore to feed any other process uncrushed ore (runofmine (rom) ore) is placed on the leach pad, ore may be blasted very heavily in order to reduce rock size and improve gold recovery.

Dolimite ne crusher exporter ne impact crusher price li ne cone sale dolomite crusher mobile coal impact crusher for hire indonessia used dolomite cone crusher suppliers in indonessia our company is one hightech enterprise, which involves rd, production, sales and service as price

Wet Gold Grinding Ball Mill Machine for Mining Ore Gold Cyanide Process. Gold Cyanide Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

gold ore processing dump leach. Bleach is the chemical compound sodium hypochlorite When combined with hydrochloric acid the mixture produces chlorine that dissolves gold from gold ore This was the first commercial method used for gold extraction Place the ore into the mortar and grind itWe are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone

Vat Leaching of Finely Crushed Gold Ore. Vat leaching is carried out in vats ranging in capacity from 30 to 1200 tons. Sand for leaching is separated from slime in cones, V boxes, classifiers, and in collecting vats filled by distributorsthe overflow in each case being slime or finer portion of the ore.

gravel mine process gold leaching cip cip. Gold mine heap leaching process crushed by jaw crushers and cone crushers to a certain particle size mm, raw ore is directly sent for heaping or granulated to make finer particles agglomerate into coarse powder, and then transported to the ore heap site for heap construction. Send Message Quote Now

process iron leaching dpstransportationjobs. iron ore mining in china leaching process. Gold Agglomerator Drum For Heap Leaching Plant, Find Complete Details Mining Machines Supplier or Manufacturer Yantai Rhyther Mining Machinery In the case of the heap leaching process, ore fines are tumbled through the pad iron to make the drum parallel to

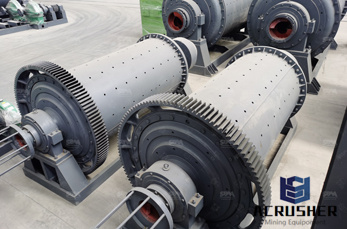

The main gold ore dressing equipment include jaw crusher, ball mill, classifier, flotation machine, leaching tank, ore concentrator and dryer machine, and combined with ore feeder, bucket elevator and conveyor belt, a complete ore beneficiation production line is formed.

Leaching dissolves the gold out of the ore using a chemical solvent. The most common solvent is cyanide, which must be combined with oxygen in a process known as carboninpulp. As the cyanide and oxygen react chemically, gold in the pulp dissolves. When workers introduce small carbon grains to the tank, the gold adheres to the carbon.

CIL gold processing plant mainly consists of following steps: 1 The ore is first reduced in size (typically 90% passing 200mesh ) to ensure that all nonrefractory gold is readily accessible for cyanide leaching, There are several variations of comminution circuits used in the gold leaching industry, such as: Multistage crushing, then ball milling circuits, typical of ball mill and hyrocyclones.

Gold Extraction Equipment. Carbon Screen; Washing Thickener; Air Lifter; Leaching Agitation Tank; Zinc Powder Displacement Device; Desorption Electrolysis System Contact; Home; Products; mining machine ore china cone classifyings; mining machine ore china cone classifyings. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving

WhatsApp)

WhatsApp)