Surface Grinding Machine Operation YouTube

#0183;#32;For more information visit here : This tutorial shows step by step how to use Surface Grinding Machine. Starting on setting u...

WhatsApp)

WhatsApp)

#0183;#32;For more information visit here : This tutorial shows step by step how to use Surface Grinding Machine. Starting on setting u...

1,473 operation of grinding machine products are offered for sale by suppliers on A wide variety of operation of grinding machine options are available to you, such as plastic. You can also choose from 1 year, 2 years, and 3 years operation of grinding machine,

A drilling machine is one of the important machine tools in the workshop.. In todays article, I will discuss the definition, parts, types, and operations of the drilling machine you should know at the end of the article, I will give you the pdf download link.. We also perform drilling operation in lathe machine too, but drill machine is made for this specific drill operations, so

Cylindrical grinding is performed by mounting and rotating the work between centres in a cylindrical grinding machine. The work is fed longitudinally against the rotating grinding wheel to perform grinding. The upper table of the grinding machine is set at 0#176; during the operation.

Different machines are used for different types of operations, such as surface grinding, cylindrical (including centreless) grinding, internal grinding, rough grinding and cutting. The two main types are: those where either the grinder or the work is moved by hand and machines

W. Brian Rowe, in Principles of Modern Grinding Technology (Second Edition), 2014. Flexible Grinding Operations and Peel Grinding. Flexible grinding operation suggests that a family of components or possibly several families can be produced flexibly on one automatically controlled machine tool. For example, it is possible that cylindrical components having several diameters and shoulders could

Each grinding machine shall be inspected regularly before use, and colour coded; Abrasive wheels, grinding or cutting discs without the manufacturers maximum RPM marked shall not be used. RPM (rotation per minute) of the wheel shall be more than a grinding machine if machine RPM exceeds than a wheel can break easily.

Grinding Machine: Types, Parts, Working amp; Operations (With

Surface grinding is used to produce a smooth finish on flat surfaces. It is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or nonmetallic substance from a workpiece, making a face of it flat or smooth.

#0183;#32;This video will explain the basic concepts of Grinding Machine and its types. This video contains copyright channel gives a glimpse of basic engi...

A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial. It is a process of metal cutting by using a rotating abrasive whee l from the surface of the workpiece. Generally, the grinding is finishing

conventional grinding machines. A grinding machine, often shortened to grinder, is one of power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting grain of abrasive on the wheel''s surface cuts a small chip

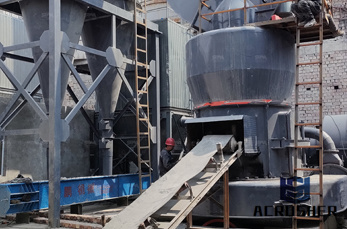

Operations that can be performed on grinding machineGrinding machine operations: The following stated below represent the operations that can be performed o. Largescale crushing amp; screening amp; milling plants. Offer efficient, costeffective services for you. Operation Of Line Grinding Machine

Turning an older machine into a modern turnkey grinding system involves an indepth knowledge of the systems mechanical, hydraulic and electrical systems as well as software and automation. Skilled in these disciplines and wellversed in global automated grinding operations, the GCH Machinery engineering and manufacturing teams are a rare find among machine builders.

Wear goggles for all grinding machine operations. Check grinding wheels for cracks (Ring Test Figure 511) before mounting. Never operate grinding wheels at speeds in excess of the recommended speed. Never adjust the workpiece or work mounting devices when the machine is operating

Grinding machine is a type of machine used to grind the workpieces. It basically uses emery or an abrasive wheel as the cutting tool. The grinding process is truly a chip producing machining process. The rough surface of the abrasive wheel spreads into small portions of the workpiece as required.

Grinding Operation an overview | ScienceDirect Topics. W. Brian Rowe, in Principles of Modern Grinding Technology (Second Edition), 2014. Flexible Grinding Operations and Peel Grinding. Flexible grinding operation suggests that a family of components or possibly several families can be produced flexibly on one automatically controlled machine

A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. (milling machine) Types Peripheral milling Slab, slotting, side and straddle milling Up Milling (Conventional) amp; down milling (Climb) Facing milling Conventional face, Partial face, End, Profile, Pocket amp; contour

Operation notes of tool grinding machine. According to the different types of shafts, it can divide into a horizontal shaft and vertical shaft grinding machine operation instructions of tool grinding machine basic structure the new machine needs to replace with hydraulic oil after three months. View All; Operation of grinding machine, operation of

WhatsApp)

WhatsApp)