How to profit from lowgrade gold mines

23/12/2018#0183;#32;In 2001 when the gold price was just 272/oz, gold mining companies had cash costs of 176 an ounce, giving a 54% margin. However, by 2006 the gold

WhatsApp)

WhatsApp)

23/12/2018#0183;#32;In 2001 when the gold price was just 272/oz, gold mining companies had cash costs of 176 an ounce, giving a 54% margin. However, by 2006 the gold

911MPE has small gold mining equipment for sale and more specifically mineral processing equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics. 911MPE offers gold mining equipment as well as processing equipment applicable to most any base metals: copper, lead, zinc, nickel, tin, tungsten and

The Gold Mine presents all the key lean principles, ranging from wellknown ideas such as pull and flow, to lesserknown yet equally important principles such as jidoka and heijunka. The book presents lean as a systemusing a realistic story to show how the principles are interrelated and how they lead to useful tools such as kanban or 5S.

Aug 03, 2018 #183; If we divide the 391 Moz of total gold production, the net free cash flow per ounce was 19. Now compare that to the 832 average gold price during the twenty year period. By focusing on the Free Cash Flow, over an extended period, we can see that the top gold mining companies haven''''t made all that much money. Get Price

62 Mining Businesses Available For Sale Worldwide Today on BFS, The World''s Largest Marketplace for Buying and Selling a Business Mining Businesses For Sale Worldwide, 62 Available To Buy Now uses cookies to save your settings, improve

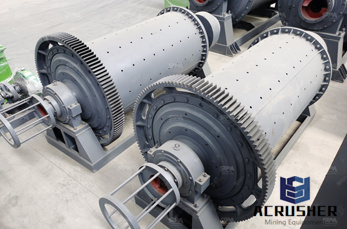

Gold Mining And Processing Flow Chart GitHub Pages. This gold mining and processing flow chart is the ore by Hubei mining crusher preliminary broken in, to a reasonable size broken through after lifting machine, feeder evenly into the ball, for ore crushing, grinding by ball mill.

18/12/2004#0183;#32;Bronze Age gold objects are plentiful, especially in Ireland and Spain, and there are several well known possible sources. Romans used hydraulic mining methods, such as hushing and ground sluicing on a large scale to extract gold from extensive alluvial (loose sediment) deposits, such as those at Las was under the control of the state but the mines may have been leased to

The lifecycle of a gold mine. People in hard hats working underground is what often comes to mind when thinking about how gold is mined. Yet mining the ore is just one stage in a long and complex gold mining process. Long before any gold can be

22/5/2019#0183;#32;For example, in the gold sector, the byproduct is quite often copper. As a case in point, a mine that produces 100,000 ounces of gold and 10,000 tonnes of copper per year at a cost of US1000 per ounce, not including revenues generated from the sale of copper, will have AISCs well below US1000 per ounce after the byproduct credits are taken

The history of Australian gold mining is one of romance, greed, tragedy, great expectations and great rewards. Gold mining was considered to be a vital part of Australia''s economy. Australia''s gold reserves were a vital and respected segment of the Australian economy until 1997 when Peter Costello sold off two thirds of Australia''s gold reserves and crashed our Australian gold mining industry.

23/1/2012#0183;#32;The result is % pure gold, which is then cast into electrodes (known as anodes) where it is then placed into an electrolytic cell. A current is then passed through the cell, with the end product being % pure gold. Step #9 Mine reclamation. After a

flow chart on gold mantelzorgleiderdorp. flow chart of gold processing to a product. Also the throughput and screening efficiency are greatly improved. gold processing flow chart of gold bearing quartz XSM is a leading global manufacturer of crushing It is the new generation product designed and produced by Flow Chart For Gold Processing cosmosms.

product flow of a gold mine As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals.

Gold processing, preparation of the ore for use in various products.. For thousands of years the word gold has connoted something of beauty or value. These images are derived from two properties of gold, its colour and its chemical colour of gold is due to the electronic structure of the gold atom, which absorbs electromagnetic radiation with wavelengths less than 5600 angstroms

By product gold mining Gold is also produced by mining in which it is not the principal product. Large copper mines, such as the Bingham Canyon mine in Ut, often recover considerable amounts of gold and other metals along with copper. Some sand and gravel pits, such as those around Denver, Colorado, may recover small amounts of gold in their washing operations. The largest producing gold mine in

A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved. Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver. This process removes 93% of the gold and 70% of the silver.

Gold Mining And Processing Flow Chart GitHub Pages. This gold mining and processing flow chart is the ore by Hubei mining crusher preliminary broken in, to a reasonable size broken through after lifting machine, feeder evenly into the ball, for ore crushing, grinding by ball mill. After the ore fine grinding ball mill into the next process step.

The processing plant at Cerro Vanguardia gold and silver mine in Argentina Mining companies in more than 130 countries turn to #187;More detailed. gold mine process flow chart Gold Ore Crusher. About gold mine process flow chart Mining equipment for mineral extraction and screening operations equipment, usually including the

WhatsApp)

WhatsApp)