Top 10 USbased miners

Aug 14, 2019#0183;#32;Southern Copper produced 883,689 tonnes copper, 70,778 tonnes zinc and million oz. silver in 2018, compared to 876,979 tonnes copper, 68,665

WhatsApp)

WhatsApp)

Aug 14, 2019#0183;#32;Southern Copper produced 883,689 tonnes copper, 70,778 tonnes zinc and million oz. silver in 2018, compared to 876,979 tonnes copper, 68,665

Dec 03, 2020#0183;#32;Ero Copper Corp.: Ero Copper is a Canadabased mining company that engages in the production and sale of copper, gold, and silver in mining locations primarily in

The slag pots and chill moulds are manufactured from either heatresistant cast iron or spheroidal graphite cast iron to provide longlasting highquality solutions. They are also suited for a number of processes, which include lead, aluminium, iron, steel, chrome, manganese, copper and other smelting applications. Using positive hydraulic control, the pot is tipped to pour molten slag into pits for cooling

Some properties of a typical copper slag are shown in Table I, and it can be observed that aircooled copper slag has a black colour and glassy appearance. The specific gravity varies with iron content, from to The unit weight of copper slag is somewhat higher than that of conventional aggregate. The absorption capacity of the

The CHAENG slag pots can be used not only in steel plants, but also in metallurgical work of copper mines As early as July 2015, the representative of Chile s largest copper mining company came to CHAENG to visit and inspect large steel casting products The Chilean copper mining company representatives expressed appreciation for the advanced casting technology of CHAENG slag pots It

Millions of tons of black slag remain from Roman smelting operations. The slag contains small amounts of gold and silver, as well as copper, showing that the Romans were interested in these precious metals. Miners today are mining brassy yellow copper quot;sulfidequot; minerals such as chalcopyrite.

Mining in Cornwall and Devon, in the southwest of England, began in the early Bronze Age, around 2150 BC, and ended with the closure of South Crofty tin mine in Cornwall in 1998. Tin, and later copper, were the most commonly extracted tin mining continued long after the mining of other metals had become unprofitable. Historically, tin and copper as well as a few other metals (

Watercooled copper launders use the freeze lining principle to reduce component wear. Lower wear means longer launder life, cutting longterm maintenance costs and downtime production losses. Many launder designs present an inherent safety risk by positioning the water cooling passages underneath the slag

Jul 08, 2019#0183;#32;Copper smelting and refining facilities produce million metric tons (MT) of smelter slag and million MT of slag tailings per year. This is a large volume of slag, however, it is very small compared to comparable waste volumes from mining and crushing operations.

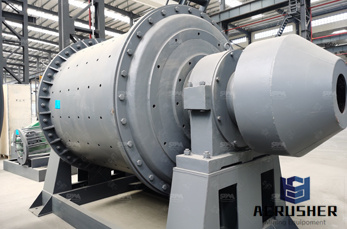

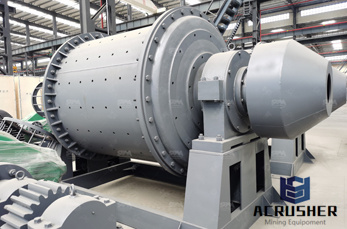

The advancements made in mining equipment, such as those achieved at General Kinematics, along with mining technology progress have resulted in growth and production in the copper mining industry. From primitive, cumbersome mining methods to compact, efficient modernday equipment, copper mining has become a costeffective, efficient process.

Dec 01, 2013#0183;#32;When the Israelites were poised to enter the Promised Land, Moses told them: Out of the mountains of [the land] you will mine copper. ( Deuteronomy 8:79 ) Archaeologists have discovered in Israel and Jordan a number of ancient mining and smelting sites, such as

Copper Mining and Processing: Everything you Need to Know

Slag from the Arizona Copper Co. smelter is poured from slag pot cars transported by two 18ton electric locomotives on a narrow gauge railroad. photos Courtesy of FreeportMcMoRan

ized in all phases of copper production. Both machine and human productivity have increased dramatically. This chapter briefly describes the technology for producing copper, from exploration, through mining and milling, to smelting and refining or solvent extraction and electrowinning. The chapter begins with an overview of the history of cop

The denser molten matte layer captures the copperiron sulphides below the unwanted upper slag layer, which is skimmed off periodically via skim bays and launders into large pots destined for rail transportation to the slag stockpile. Matte with 42% copper content is tapped off periodically via open launders into ladles, which are transferred

After use, clinker dust turns into copper slag, which is then recycled back into raw materials at the cement plants. Mitsubishi also recycles and recovers rare metals, as well as undertaking ongoing expansion of its preprocessing combustion, sampling, analysing and processing facilities, which are crucial to effective recycling.

The engineering properties of steel slag and copper mine tailings were reviewed and their various areas of application are highlighted. mining residues can be recovered as secondary supplies

#0183;#32;Copper slag is a byproduct created during the copper smelting and refining process. As refineries draw metal out of copper ore, they produce a large volume of nonmetallic dust, soot, and rock. Collectively, these materials make up slag, which can be used for a surprising number of applications in the building and industrial fields.

Copper extraction refers to the methods used to obtain copper from its conversion of copper consists of a series of physical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.. As in all mining operations, the ore must usually be beneficiated (concentrated).

AZ, Douglas, Arizona, Copper Queen Smelter, Slagpots, Mining Scene, Mine: Product Photo: Click Image for Larger Preview: Product Information: This is a nice vintage early printed postcard showing a scene of the slagpots inside the Copper Queen Smelter in Douglas, Arizona. Publisher: Newman No 13. The corners have light wear. The image is

Basic properties of copper slag Copper slag properties in reverberatory furnace smelting, flash smelting, and other processes are similar. A typical smelting slag contains approximately 3045% FeO, 3040% SiO2, 510% Al 2 O 3, 26% CaO, and 24% MgO (Kokal, 2006).

Introduction of CHAENG slag pots CHAENG (Xinxiang Great Wall Steel Casting Co., Ltd) Website: Email: casting

Nov 25, 2019#0183;#32;The largest copper mine in Africa, Kansanshi is owned and operated by Kansanshi Mining PLC, which is 80% owned by a First Quantum subsidiary. The remaining 20% is owned by a subsidiary of ZCCM. The mine is located approximately 6 miles north of the town of Solwezi and 112 miles to the northwest of the Copperbelt town of Chingola.

WhatsApp)

WhatsApp)