Pete''s Patch Fact Sheets Gardening Australia

But remember all tomato plants are potash hungry. So add a pinch of sulphate of potash to make the leaves lovely and firm and disease resistant. Gardening Australia podcasts.

WhatsApp)

WhatsApp)

But remember all tomato plants are potash hungry. So add a pinch of sulphate of potash to make the leaves lovely and firm and disease resistant. Gardening Australia podcasts.

#0183;#32;The Lake Way project is a sulphate of potash (SOP) operation being developed by Salt Lake Potash (SO4) in the Goldfields region of Western Australia (WA). It is expected to produce 245,000tpa of SOP with an expected mine life of more than 20 years.

Contact Us. Australian Potash Limited: Suite 31, 22 Railway Road Subiaco Western Australia 6008 PO Box 180 Subiaco Western Australia 6904 Tel: +61 8 9322 1003 Twitter: OzPotash

Flotation collectors optimized performance. Flotation of potash Potash is the most important source of potassium in fertilizers. Flotation is one of the major methods used to upgrade the potash. We are the worldleading supplier of collectors to the potash industry which we have been serving for over 70 years. For the direct flotation of potash, we can deliver either standard amine

An Overview Of Potash Flotation Hatch Ltd. More than 70% of potash is produced worldwide by froth flotation. Flotation of potash was developed in the early 1930s. Amines are widely used for flotation of sylvite (KCl) from halite (NaCl) and insoluble materials such as clays. Amine collector is also absorbed by clays. Therefore, clays areget price

Potash Flotation Plant Australia From Ethiopia An Overview Of Potash Flotation Hatch Ltd More than 70 of potash is produced worldwide by froth flotation Flotation of potash was developed in the early 1930s Amines are widely used for flotation of sylvite KCl from halite NaCl and insoluble materials such as clays Amine collector is also absorbed by clays Therefore clays areget price.

Flotation of potash was developed in the early 1930s. Amines are widely used for flotation of sylvite (KCl) from halite (NaCl) and insoluble materials such as clays. Amine collector is also absorbed by clays. Therefore, clays are usually separated by scrubbing and desliming prior to flotation.

It is notable that there is no commercial production in Australia which consumes a combined total of ~420ktpa MOP and SOP being the most recent figures for 2017. Given these factors, Kalium Lakes is of the view that an opportunity exists to capture the Australian supply market for SOP with opportunities to extend into Asia and the subcontinent.

#0183;#32;Australian Potash produced 98% pure K2SO4 at the pilot processing plant, in January 2019. Image courtesy of Australian Potash Limited (). The Lake Wells Potash Project (LWPP) is a palaeochannel brinehosted sulphate of potash (SOP) project in Yilgarn Craton, Western Australia.

#0183;#32;The Lake Wells Potash Project (LWPP) is a palaeochannel brinehosted sulphate of potash (SOP) project in Yilgarn Craton, Western Australia. Australian Potash () is the project developer. The project is expected to produce million tonnes (Mt) of SOP over an estimated mine life of 20 years.

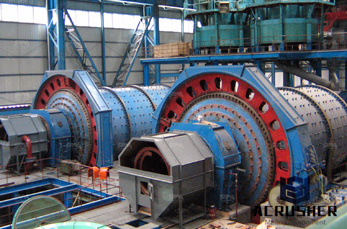

ICL Iberia extracts sylvinite in its mines, near Barcelona. In order to double its current production capacity for potash, SerIDOM has been contracted to carry out the design, construction and commissioning of its new flotation plant. Potash will be separated out from the accompanying salt using state of the art equipment to reach industry highest recovery levels.

Australian farmers consume a quarter of a million tonnes of it a year, but as yet there is no domestic production of potash. However, that looks set to change, with the country''s first SOP mine

Australia is proving that there is potential to produce potash here in the coming years. A number of junior miners have been advancing sulphate of potash (SOP) projects in Western Australia to

Potash occurs in soft deposits generally associated with sodium chloride and varying amounts of clay slime, which because of its colloidal character, complicates the beneficiation process. Potash ores generally contain 20 to 40 percent KCL with the balance being NaCl and a small amount of clay slime, the latter usually in the order of 1 to 1#189;%. Flotation has been developed as the principal

#0183;#32;Flotation of potash was developed in the early 1930s. Amines are widely used for flotation of sylvite (KCl) from halite (NaCl) and insoluble materials such as clays. Amine collector is also absorbed by clays. Therefore, clays are usually separated by scrubbing and desliming prior to flotation.

A review of potash flotation shows that there is still room for improvement in both coarse and fine potash flotation. The present paper reviews the most significant flotation parameters including reagent type and dosage, flotation circuits, flotation equipment size and new developments in potash flotation.

#0183;#32;Potash is not a name when it comes to mining in Australia. It has, however, started to emerge on the radar. Ask a Canadian miner, or perhaps a Russian, and their familiarity with potash

WhatsApp)

WhatsApp)