critical speed of a cement mill

Raw mills usually operate at 7274% critical speed and cement mills at 7476%. Calculation of the Critical Get Price Here! critical speed of of ball mill

WhatsApp)

WhatsApp)

Raw mills usually operate at 7274% critical speed and cement mills at 7476%. Calculation of the Critical Get Price Here! critical speed of of ball mill

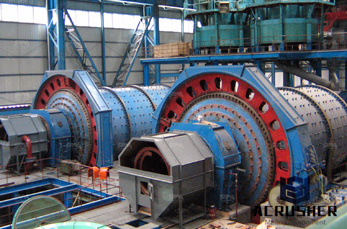

Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills. Closed circuit ball mill with two compartments for coarse and fine grinding and a drying compartment with lifters are generally found in cement plants for raw material grinding.

Critical Speed Formula For Ball Mill In Meters. Cement ball mill critical speed formula ball mill critical speed mineral processing metall the critical speed of a rotating mill is the rpm at which a grinding medium will begin to centrifuge, namely will start rotating with the mill and therefore cease to carry out useful work ball mills have been successfully run at speeds between and percent

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula The mill speed is typically defined as the percent of the Theoretical

Raw Mill In Cement Plant Cement Making Plant This paper mainly introduces the raw mill in cement plant. In order to achieve the desired setting qualities in the finished product a quantity (28 but typically 5 ) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder.

SAGMILLING .:. Mill Critical Speed Determination. Oct 23, 2015#183; Cement is an energyintensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost [].The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns.

Attentions To Cement Ball Mill''''S Critical Speed. Ball mill Wikipedia, the free encyclopedia raw mills critical speed cement 18108, A ball mill is a type of, The grinding works on the principle of critical speed, and it is widely used in production lines for powders such as cement,Ball Mill With Full Formula mayukhportfoliocoin . Get Price

Mill Speed Critical Speed. Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

Feeling Density Of Raw Mill Of Cement Line. 2015 01 07 Raw mills usually operate at 72 74 critical speed and cement mills at 74 76 . Calculation of the Critical Mill Speed G weight of a grinding ball in kg. w Angular velocity of the mill tube in radial second. w = 2 (n 60) Di. Read More

critical speed in a ball mill. Raw mills usually operate at 7274% critical speed and cement mills at 7476%. Calculation of the Critical Mill Speed grinding in a ball mill should : 2/5 Steel Ball Mills and Milling Equipment | Paul O Abb. chat online

Raw mills usually operate at 7274 critical speed and cement mills at 7476 32 Calculation of the Critical Mill Speed G weight of a grinding ball in kg w Angular velocity of the mill tube in radialsecond w 2314n60 Di inside mill diameter in meter effective mill diameter n Revolution per

CEMENT MILL OPTIMISATION CASE STUDY Batra*, Mill speed rpm GM in I chamber 107 t Critical speed 76 % GM in II chamber 217 t Separator Sepax 450M222 Separator Cyclone 4 nos. Separator motor 300 kW

The smaller grades are occasionally cylindrical (quot;pebsquot;) rather than spherical. There exists a speed of rotation (the quot;critical speedquot;) at which the contents of the mill would simply ride over the roof of the mill due to centrifugal action. The critical speed (rpm) is given by: n C = / d, where d is the internal diameter in metres. Ball mills are normally operated at around 75% of critical speed, so a mill with

Cement mill notebook SlideShare. 07/01/2015 Raw mills usually operate at 7274% critical speed and cement mills at 7476%. Calculation of the Critical Mill Speed: G: weight of a grinding ball in kg. w: Angular velocity of the mill tube in radial/second. w = 2**(n/60) Di: inside mill diameter in meter (effective mill diameter). n: Revolution per minute in rpm.

At rotational speeds above the critical speed of a mill, the contents are simply forced against the sides of the drum by centrifugal force with little or no grinding action. The size of the balls is also an important consideration in a cement mill. If the balls are too large, the raw material will not be

#0183;#32;Raw mills usually operate at 7274% critical speed and cement mills at 7476%. Calculation of the Critical Mill Speed: G: weight of a grinding ball in kg. w: Angular velocity of the mill tube in radial/second. w = 2**(n/60) Di: inside mill diameter in meter (effective mill diameter). n: Revolution per minute in rpm.

WhatsApp)

WhatsApp)