What is the best way of detecting the Processing version

Processing Forum Recent Topics. All Forums

WhatsApp)

WhatsApp)

Processing Forum Recent Topics. All Forums

The gold prices used in this table and chart are supplied by FastMarkets. Where the gold price is presented in currencies other than the US dollar, it is converted into the local currency unit using the foreign exchange rate at the time Processing, smelting and refining gold.

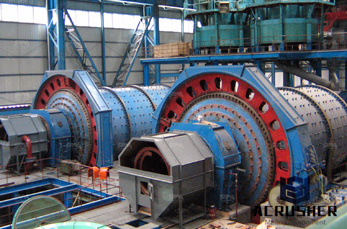

Of all the methods of extracting gold amp; processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page offers a comparative review of gold recovery

#0183;#32;Im not trying to say hes misleading you, but you need to understand that you will never become Biohack simply by following his guides. And youll never surpass him that way. For the Most Profit Processing. If you want the best results, create your own spreadsheet. Put as many processing recipes as you can in it and use some formulas for

Though Gold is not the primary product, this mine produces more Gold than any other mine in the world. The final category of gold mining is the processing of Gold ore. This method is largely becoming deprecated as the yield of Gold is often very low and the environmental impact

best way of processing the gold +More. Gold Mining and Processing: Everything you Need to Know. (80 to 90%) in a standard. is a long way from any water and dry processing may well be the best way to go. Get Quote; Rock Crushing methods and How to recover gold from Ores.

Cornstarch Replaces Cyanide In Clean New Gold Extraction Method. Scientists accidentally discover a new way to isolate gold that is much safer than existing processes, which use toxic cyanide.

Gold processing Gold processing Refining: Gold extracted by amalgamation or cyanidation contains a variety of impurities, including zinc, copper, silver, and iron. Two methods are commonly employed for purification: the Miller process and the Wohlwill process. The Miller process is based on the fact that virtually all the impurities present in gold combine with gaseous chlorine more

Step #7 Processing (onsite) Once ore is extracted, processing it into pure gold must be done. Ore is first crushed and then undergoes various processes depending on the nature of associated minerals. Processing lowgrade ore is relatively simple while higher grades require more extensive processing. Step #8 Refining (offsite)

#0183;#32;If your gold is unrefined, your best option may be to ship it to a refiner. These processes may be challenging and costprohibitive for you. Another issue is that if you try to refine your own scrap, you may only recover the gold and not the other precious metals that

The lifecycle of a gold mine. People in hard hats working underground is what often comes to mind when thinking about how gold is mined. Yet mining the ore is just one stage in a long and complex gold mining process. Long before any gold can be extracted, significant exploration and development needs to take place, both to determine, as accurately as possible, the size of the deposit as well

Gold can be concentrated and recovered by applying different gold refining process methods and the final product has variable quality. In this way, it is necessary to have a better marketable product so that the incomes can be improved. Then, we have two smelt and cast the gold into bars called bullion or Dore. The name bullion is restricted to the precious metals, refined or unrefined, in

How to Process Gold Concentrate. Join Rob Goreham of 49er Mining Supplies as he explains how to seperate gold from other materials. See the KEENE Super Concentrator, Heavy Hitter Magnet, Blue Bowl, and Falcon Metal Detector used to acheive maximum results.

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of

Smelting gold usually involves hightech and highcost tools to perform. Mostly, mining companies do the procedure, which sees one material bonded to or released from another in the presence of extreme heat. However, prospectors, and people at home, can smelt their old gold using some simple steps.

Gold processing preparation of the ore for use in various products. Native gold is the most common mineral of gold accounting for about 80 percent of the metal in the Earth s crust. It occasionally is found as nuggets as large as 12 millimetres ( inch) in diameter and on rare occasions .

Processing, smelting and refining gold | World Gold Council

Gold is an almost nonreactive metal, but halogens chlorine, bromine, fluorine and iodine can dissolve it. Chlorine is the cheapest and lightest product that can achieve this. Bleach is the chemical compound sodium hypochlorite. When combined with hydrochloric acid, the

Extracting Gold Extracting gold is a term related to gold. Learn about extracting gold at HowStuffWorks. which can be recycled for future processing. Finally, the goldbearing solution is ready for electrowinning, which recovers the gold from the leaching chemicals. Get the best of HowStuffWorks by email!

Gold flotation method is suitable for the extraction of goldbearing quartz veins with fine gold particles and good floatability, goldbearing altered rock type ores, and for ores containing various sulfides. This gold processing method is suitable for small to medium or large gold processing plants. 4.

WhatsApp)

WhatsApp)