coal washery plant enlistment process

Coal preparation plant Wikipedia

WhatsApp)

WhatsApp)

Coal preparation plant Wikipedia

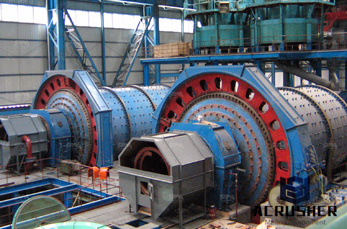

process coal washery . What Happens In Coal Washery Process. Process of coal washery plant coal preparation plant is a facility that washes coal of soil and rock, crushes it into graded coal needs to be stored at various stages of the preparation process, and cyclone is the heart of the washing unit in a heavy media washeryead more.

Metallurgical ContentThe Problem with Coarse and Fine Coal BeneficiationFine Coal Flotation Circuit FlowsheetCoarse Coal Flotation CircuitModern Coal Preparation AdvantagesThe Problem with Coal Recovery and Cleaning by FlotationThe Coal Recovery and Cleaning by Flotation Flowsheet DiagramFlowsheet AFlowsheet BMODERN COAL PREPARATION ADVANTAGal Flotation

concerned. The washery shall be operated in conformity with the same. The Washery operator shall ensure closewatercircuit operation so that no effluent is discharged in the natural streams. Right to Access The prospective Washery operator shall provide basic technological features of the washery to coal companies prior to set up.

The ash percentage in coal can be reduced by a process known as Coal Washing in a coal washeries which are established mostly in Jharia, Raniganj, Bokaro and Karanpura coalfields for treating prime and medium coking coals. Coal Washery by Bharat...

What Happens In Coal Washery Process. coal washery flow chart in india jaw crusher flow diagram india:. coal washery process flow diagram india from .. diagram for sale in Coal Crushing Plant Flow Sheet Coal preparation plant Wikipedia A coal preparation plant Coal handling is part of the A cyclone is the heart of the washing . Typical flow sheet of a coal processing plant in

Coal washing is a process that is undertaken in a coal washery or coal preparation plant (CPP) where coal is refined or cleaned of impurities. Coal washing involves using water, mechanical techniques and relies on gravity and the difference of density between coal and it''s impurities which are usually more densely packed due to the fact that they are inorganic. Safeopedia explains Coal Washing

Mar 27, 2019#183; The equipment and process of the coal washing plant are related. The three most basic processes of the coal wash plant are the preparation work before the sorting (crushing, screening, grading), the sorting operation, and the processing of the selected products. At the same time, heavy medium coal preparation includes five major processes: coal.

The scheme used in physical coal cleaning processes varies among coal cleaning plants but can generally be divided into four basic phases: initial preparation, fine coal processing, coarse coal processing, and final preparation.

Separating Process. Magnetic Separator; Sf Flotation Cell; Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation; Magnetic Drum; Spiral Chute; Bf Flotation Cell ; Dry Separator With Eccentric Rotating Magnetic System; Kyf Air Inflation Flotation Cell; Gold Extraction Equipment. Carbon Screen; Washing Thickener; Air Lifter; Leaching Agitation Tank; Zinc Powder

Coal washing Coal that comes from a mine is a complex mixture of materials with a large variety of physical properties. In addition to the coal itself, pieces of rock, sand, and various minerals are contained in the mixture. Thus, before coal can be sold to consumers, it must be cleaned. The cleaning process consists of a number of steps that results in a product that is specifically suited to

Coal Beneficiation Process Diagram The Problem with Coarse and Fine Coal BeneficiationThe Problem with Coal Recovery and Cleaning by FlotationCoal Flotation ProblemsCoal Beneficiation Process Economic and operating conditions make it important to provide a simple, low cost, efficient method for recovering fine coal from washery waste. Not only is the water pollution problem a serious one, but

The environment ministry now in its latest note has said, In the overall scheme of coal, mine, washery and power plant, the extent of ash content in mined coal remains the same. Business Standard has reviewed the note. According to industry calculations, coal washing improves the quality of coal by reducing the ash content to 33 per cent from an earlier 4045 on an average for Indian

Coal washing is a process that is undertaken in a coal washer or coal preparation plant (CPP) where coal is refined or cleaned of impurities. Coal washing involves using water, mechanical techniques and relies on gravity and the difference of density between coal and it''s impurities which are usually more densely packed due to the fact that they are inorganic.

what happens in coal washery process. Coal Washery Process Flow Diagram . Coal Washery Process Flow Diagram. Boiler Presentation #183; One Of the very Good presentation by A2z Employee Boiler Presentation 1. Get Price. coal washery and meaning . coal washery: An establishment where coal is cleaned from slate and other impurities by mechanical processes which use water and take

Process of coal washery plant . A coal preparation plant is a facility that washes coal of soil and rock, crushes it into graded Coal needs to be stored at various stages of the preparation process, and . A cyclone is the heart of the washing unit in a Heavy Media Washery. How Coal is managed in the giant Coal Handling Plants of May 04, 2017 #183; Coal still is the main source of Electricity

Home; Products; processes of grinding in iron ore washery plant; processes of grinding in iron ore washery plant

Coal washing. Coal that comes from a mine is a complex mixture of materials with a large variety of physical properties. In addition to the coal itself, pieces of rock, sand, and various minerals are contained in the mixture. Thus, before coal can be sold to consumers, it must be cleaned. The cleaning process consists of a number of steps that results in a product that is specifically suited to the needs

WhatsApp)

WhatsApp)