EnergyEfficient Technologies in Cement Grinding | IntechOpen

10 #0183;#32;Oct 23, 2015#0183;#32;Material is fed into the gap between the rolls, and the crushed material leaves as a compacted cake.

WhatsApp)

WhatsApp)

10 #0183;#32;Oct 23, 2015#0183;#32;Material is fed into the gap between the rolls, and the crushed material leaves as a compacted cake.

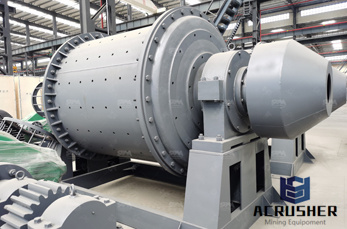

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance. With more than 4000 references worldwide, the FL ball mill

Ball mills are commonly used in the manufacture of Portland cement and finer grinding stages of mineral processing. Industrial ball mills can be as large as m (28 ft) in diameter with a 22 MW motor, [4] drawing approximately % of the total world''s power (see List of countries by electricity consumption ).

1 #0183;#32;For the cement industry the ball mill was really an epochmaking breakthrough optimizatkon for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Cement Vertical Mill vs Ball Mill.

Therefore, the selection of a reasonable cement grinding system plays a key role in energy

Oct 23, 2015#0183;#32;Material is fed into the gap between the rolls, and the crushed material leaves as a compacted cake. The energy consumption is kWh/t and about 10 kWh/t when recycling of the material is used. The comminution efficiency of a HPGR is better than ball mills such that it consumes 3050 % of the specific energy as compared to a ball mill.

Energy consumption is typically half that of a ball mill. However, the narrowness of the particle size distribution of the cement is problematic, and the process has yet to receive wide acceptance. Highpressure roll presses Edit

Jul 18, 2016#0183;#32;The consumption of energy by the cement grinding operation amounts to one third of the total electrical energy used for the production of cement. The optimization of this process would yield substantial benefits in terms of energy savings and capacity increase. Optimization of the

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

May 01, 2020#0183;#32;Electrical energy consumption of cement mill plant: Ball mill (kWh/t) : : : Separator fan (kWh/t) : : 2. 5: Others (kWh/t) : : : Sum (kWh/t) : : : Production: Production rate (t/h) 213: : : Specific surface area (Blaine) cm 2 /g: 3500: 3010: 3030: Residual on sieve 45 m (%) : : : Efficiency: First law efficiency (%) : :

EnergyEfficient Technologies in Cement Grinding | IntechOpen

Ball mill with Central Drive Mill length Mil l diame te r M il l di amet er 5 3 2 3 2 1 3 5 6 6 4 4 Ball mill with Sid e Driv 1 Inlet 2 Outlet casing 3 Slide shoe bearing 4 Main gearbox 5 Mill motor 6 Auxiliary drive 1 3 Ball mill for cement grinding 3 Cement grinding taking on the tough tasks Cement ball mills have to achieve the desired

Effect Of Grinding Method On Energy. In the conventional process of cement production 3080 kWht specific energy is consumed in cement grinding which equals 30 of the total energy consumption Furthermore approximately 6070 of the total electrical energy used in a cement plant is utilized for the grinding. Read More

In this study, certain measures are implemented in an existing raw mill in a cement factory and the specific energy consumption of the unit is calculated to be kWh/ton farine.

Application of SPI for Modeling energy consumption in Thus, the ball mill consumes kWh/t, more energy than the SAG mill in producing the final product.. a Starkey mill was used to measure SAG mill power. Ingenier#237;a e Investigaci#243;n Determining cement ball mill dosage by

WhatsApp)

WhatsApp)