411 Vertical Mills Operations_V10 Scribd

411 Vertical Mills Operations_V10 Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. ddfqf

WhatsApp)

WhatsApp)

411 Vertical Mills Operations_V10 Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. ddfqf

FL has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades. The OK mill has been FLs standard cement VRM since 1993. monitors the machinery and facilitates operation. OK cement mill roller design OK raw mill roller design Quality and

Operation. Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the

Recently, especially from 1980s, grinding system using the vertical roller mill, which has effective grinding performance, is developed and applied in the cement grinding process. Descriptions . Basic equipment structure of the vertical roller mill for cement grinding is the same as the vertical roller mill of raw material and coal grindings.

#0183;#32;Request PDF | On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance | Find, read

Today the airswept vertical roller mill is the standard solution for coal grinding installations. And thanks to our continuous refinement of the ATOX coal mill over the years, todays leading airswept vertical roller mill is the compact ATOX. Offering high reliability,

operation maual for vertical roller mill. Vertical Roller Mill Operation,LM Vertical Grinding Mills. 2, the use of more than 500 hours to replace roller vertical roller mill roller, roller rolling bearing internal Settings must be clean, damaged parts should be replaced in a timely manner, timely refueling tools available manual pump. 3, vertical roller mill in use process, should be fixed

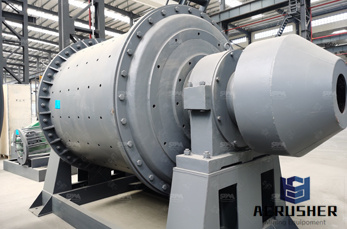

Tube mill with precrushing unit vertical shaft impactor (VSI) or horizontal impact crusher (HIC) Roller press in semi finish and finish grinding mode Vertical roller mill (VRM) Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills

;32;the vertical roller mill has been widely used in regrinding and fine grinding operations of non . vertical roller mill operation . the entire milling process of the vertical roller mill is carried out in a confined . Learn More

vertical shaft impact crusher VSI crushers use a different approach involving a high speed rotor with wear resistant tips and a crushing chamber designed to ''throw'' the rock against. More information

FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche , Germany, and Steven McGarel, Senior Consultant, USA LMmaster_ 1

INDUSTRIAL CASE STUDY: THE CEMENT INDUSTRY. operation sites account for over 90% of the California cement industry''s electric. Energy intensity can be examined by combining information on energy. materials are ground into a flowable powder in horizontal ball mills or in vertical roller mills. ball mills in combination with roller presses, roller mills, or roller presses.

#0183;#32;Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding circuits.

thermal conditions, every new bar entering the mill creates an impact, and sometimes there are really severe rolling accidents, due to faults by operators, weak rolled materials with internal defects, or because of other problems in a mill such as a power cut, mechanical problems of transportation or in the water cooling system.

Raymond#174; Roller Mills Deliver Maximum Productivity 35 inch Raymond Vertical Mill Raymond 200 VERTICAL MILLS IMP MILLS The imp mill is extensively used for processing and pulverizing of many materials. Typical grinding applications include CLAY, GYPSUM, KAOLIN, TALC, PIGMENTS,

Vertical Roller Mills Do not believe screen values unless you have checked them Vertical Roller Mills Basic Calculations For Operation of VRM s. Vertical Roller Mills Calculation of Specific Roller Force F Roller = FR weight + FR hydraulic (KN) A Roller = W roller X D roller (M2)

grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system. However, despite these benefits, applications of the vertical roller mill

WhatsApp)

WhatsApp)