(PDF) THE CEMENT MANUFACTURING PROCESS | Junaid

is a platform for academics to share research papers.

WhatsApp)

WhatsApp)

is a platform for academics to share research papers.

30/8/2012#0183;#32;Cement Manufacturing Process Phases Raw material extraction/ Quarry Grinding, Proportioning and Blending Preheater Phase Kiln Phase Cooling and Final Grinding Packing amp; Shipping

Manufacturing of Portland Cement Process and Materials. 1. WET Process. In the wet process, first of all, the newly quarried limestone is crushed into smaller pieces.

26/9/2020#0183;#32;The manufacturing of cement generally involves four steps: Mixing:. The mixing of raw materials can be done either with dry process or wet process. In dry process the calcareous... Burning:. The process of burning is carried out in rotary kiln and the rotary kiln is lined with refractory bricks.

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Preparing Portland cement 1 The limestone, silica, and alumina that make up Portland cement are dry ground into a very fine powder, mixed... 2 The clinker is then cooled and ground to a fine powder in a tube or ball mill. A ball mill is a rotating drum filled...

13/12/2018#0183;#32;The specific feature of the wet process is that the raw materials are prepared in water whereas in the dry process the materials are ground and mixed dry. The flowsheet diagram of the wet process for manufacturing Portland cement is given in Figure The limestone is

Stage of Cement Manufacture. There are six main stages of cement manufacturing process. Stage 1 Raw Material Extraction/Quarry. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches.

The heated air from the coolers is returned to the kilns, a process that saves fuel and increases burning efficiency. After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone. Cement is so fine that 1 pound of cement contains 150 billion grains.

9/7/2020#0183;#32;The wet process of cement manufacturing is divided into a number of stages. a) Raw material extraction. b) Grinding. c) Proportioning and mixing and preparing composition based on the raw material purity. e) Preheating the composition. f) Burning the composition in a kiln to form clinkers.

7/12/2020#0183;#32;The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine grinding. Some of the main ingredients used to make cement include limestone, clay, shale, iron, and sand. Different manufacturing techniques will use either wet or dry grinding, but each

At cement plant, according to different raw materials preparation methods, cement manufacturing can be divided into the dry process (including semidry process) and wet process (including semiwet process). Next, we will discuss the wet process of cement manufacturing in details.

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 #176;C in a cement kiln.

Methods of Manufacturing Process of Cement. At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process. The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry state.

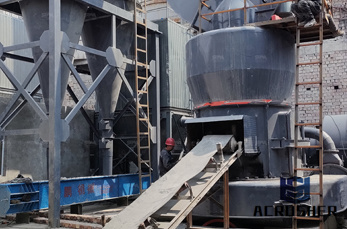

Portland Cement Manufacturing: Raw materials grinding. Mixing this material in certain proportions depending upon their purity and, Preparing Composition. Burning this composition in a kiln at a temperature of about 1300 to 1500#176;C, The process out clinker is

Manufacture of Portland Cement Materials and Process

20/7/2020#0183;#32;P ortland cement is by far the most common type of cement in general use around the world. This articles looks at the cement manufacturing process in 4 steps. Step 1: Mining. The first step of Cement manufacturing process is to quarry the principal raw

9/7/2020#0183;#32;WET PROCESS OF CEMENT MANUFACTURING a) RAW MATERIAL EXTRACTION. Major raw material involved in the cement manufacturing process is limestone. Cement... b) RAW MATERIAL GRINDING. The raw materials calcareous (lime) extracted are crushed to make a size of 6 inch and further... c) PROPORTIONING MIXING

WhatsApp)

WhatsApp)