Calculating Ball Mill Throughput

Ceramic Ball Mill Calculation, Stone Crushers China Here you can get cement ball mill throughput calculation from company, you can choose online server or leave us a Read more cement ball mill throughput calculation

WhatsApp)

WhatsApp)

Ceramic Ball Mill Calculation, Stone Crushers China Here you can get cement ball mill throughput calculation from company, you can choose online server or leave us a Read more cement ball mill throughput calculation

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize just in case. Well, this safety factor can cost you much in recovery and/or mill liner wear and

*The RPM and Chip Load that automatically populates in this calculator are the factory suggested parameters for running the desired tool. Altering the Chip Load or RPM settings in any way without prior written approval from an authorized agent of CGC/Gorilla Mill will void any guarantee or warranty nor will CGC/Gorilla Mill or its agents be liable for any consequential damages due to said

calculation of production cost stone crusher indonesia 50kg ceramic ball mill, processing of powder metals, ceramics, glass #183; 5tph ball mill, project cost to... Get Price RATE OF CERAMIC BODY GRINDING IN A BALL MILL

Milling Speed and Feed Calculator Determine the spindle speed (RPM) and feed rate (IPM) for a milling operation, as well as the cut time for a given cut length. Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill.

Ball Mill Design/Power Calculation. Ball Mill Power Calculation Example #1. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing #188; inch (6350 microns). The required product size distribution is

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

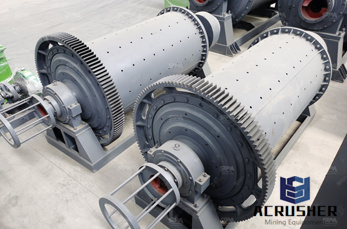

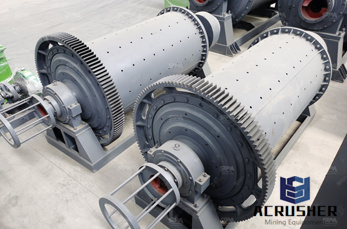

Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., Ltd is best Mining Ball Mill, Ceramic Ball Mill and Cement Ball Mill supplier, we has good quality products amp; service from China.

Ceramic ball mill is mainly used in material mixing, grinding. Henan Fote Heavy Machinery Co., Ltd has two kinds of grinding ceramic ball mill, one is dry grinding ceramic ball mill, and another is wet grinding ceramic ball mill. The machine can use different liner types according to different production needs.

ceramic ball mill calculation. Jyoti Ceramic Industries Pvt. Ltd. D = Internal Dia of the Mill in cms. after lining L = Internal length of the mill in cms. after lining. To calculate grinding media charge for continuous type ball mill, M = x D2 x L Example To calculate grinding media charge for a 180 cm dia x 180 cm long batch type ball mill with Duralox 50 mm thick bricks.

calculation of ball mill charge volume. The optimal ball diameter in a mill. of the equation for determining: When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory Most solids will decrease in volume as the particle size is reduced, so you may...

Ceramic Ball Mill Repair. Aamp;B Industrial Ceramics is a South Carolina based supplier and installer of wear resistant ceramic linings and media in the ball mill industry. We own a complete line of equipment to handle small and large jobs in either the ceramic or refractory fields.

Ceramic ball mill. Capacity (t/h) : Motor power (kw) : Ceramic ball mill is mainly used for mixing, grinding process dry or wet. Based on different production needs, it

Ceramic Ball Mill Volume Calculator. The following presents some of the research work conducted on the outotec higmill grinding rotor design, and why the higmill is positioned as the most economical fine grinding mill typethe technologyhe higmill is a stirred mill, which has a stationary shell, with a rotating shaft and mixing elements to agitate the small diameter ceramic media.

about us. GAOTENG was founded in 2000, specialized in grinding media (such as:flint pebble, silex lining brick, alumina ball amp; alumina lining brick) for ceramic industry, cement, glass, quartz and zirconium silicate industry etc., exported to more than 30 countries and regions around the world, Southeast Asia, the Middleeast, Japan, America, Europe with over 140 customers.

RATE OF CERAMIC BODY GRINDING IN A BALL MILL. Mar 15, 2005 Key words: ball mill, point of contacts, grinding rate, ceramics. form for discrete fractions was used in

D = Internal Dia of the Mill in cms. after lining L = Internal length of the mill in cms. after lining. To calculate grinding media charge for continuous type ball mill, M = x D2 x L Example To calculate grinding media charge for a 180 cm dia x 180 cm long batch type ball mill with Duralox 50 mm thick bricks. Formula to be used is

For overflow ball mills, the charge should not exceed 45% of the mill volume . For grate discharge mills, the charge should occupy about 50% of the mill volume . Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R,,

WhatsApp)

WhatsApp)