CLINKER REACTIVITY Key to Cement Performance and

CLINKER REACTIVITY Key to Cement Performance and CO2 abatement. Published on December 16, 2015 December 16, 2015 94 Likes 17 Comments

WhatsApp)

WhatsApp)

CLINKER REACTIVITY Key to Cement Performance and CO2 abatement. Published on December 16, 2015 December 16, 2015 94 Likes 17 Comments

Reliable and effi cient cement production B / Edition 0616 replaces edition 0315 Optimally equipped with our speciality lubricants 4 Lubricants for raw cement plant transport 6 Lubricants for crushing processes 8 Lubricants used in clinker production 20 reliability optimised consumption and achievement of the

Clinker bed height Installed Operation Grey and white cement, minerals 500 12,000 tpd 42 45 t/m 2/d 800 1,500 t/m/d 800 mm Nm 3/kg cl Nm 3/kg cl Hydraulics Stroke length Strokes /min 300 mm 3 5 normal 8 max Roller crusher Design Capacity Roller speed Drive Intermediate or end crusher 500 12,000

Our objective is to ensure that Buyers are well informed about the reliability, current production schedule and financial compliance of the major suppliers in India. Our clinker manufacturer, however, are real and have a good and long track record in cement manufacturing industries.

Higher the AM, lighter the color of clinker (cement). Normal range of SM is MgO is commonly present in raw meal. Some of the MgO (2%) is accommodated into the clinker mineral structure, while as extra MgO forms a crystal called periclase and causes mortar expansion. MgO up to 4 % is found common in clinker.

Cement Clinker Substitution. Cement clinker substitution occurs when clinker, the primary material used in cement manufacturing, is substituted with other cementitious materials, such as coal fly ash or blast furnace slag. Because these materials are byproducts of other industrial and energy processes and can displace the need to create clinker, the use of these substitutes can significantly

cement to be produced keeping the quality of cement equal or above the required standard. For instance (Clinker+Pozzolana+Gypsum) are proportioned and milled to produce PPC type of cement, (Clinker+Gypsum) to Produce OPC type of Cement, (Clinker+Gypsum+Limestone) to produce PLC type of cement, (Special clinker +

Clinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products. The lumps or nodules of clinker are usually of diameter 325 mm and dark grey in color. It is produced by heating limestone and clay to the point of liquefaction at about 1400#176;C1500#176;C in the rotary kiln.

Portland cement clinker thermochemistry. A wide range of temperature values are found in the literature. Despite the importance of the reaction, the state of knowledge is still poor, perhaps because it is difficult to determine equilibria in a reaction that is not smoothly reversible, and also because of the extraordinary difficulty in getting calcite samples of adequate purity.

#0183;#32;Re: clinker factor. The majority of Portland cement clinker manufactured around the world has a lime saturation of between 90 and . This means that tonnes of raw mix are required and tonnes of CO2 are lost due to calcination of the CaCO3 in the raw material.

Blazing the trail in reliability. All Beumer Group amp; Co. KG. The Turkish cement manufacturer G#246;ltas Cemento, located close to Isparta, From the kiln cooling system to the silos: the safe and economical transportation of hot materials like clinker is crucial in cement plants.

The aim of this work is to develop an effective and practicable method to evaluate the coatability of cement clinker on basic refractory bricks, susceptible to be translated in numbers. Determinations of the dominant influential factors, and assessment of reliability, as well as of coating mechanisms on different basic bricks, are to be tackled.

Clinker Cement; 1: Clinker is a nodular material which is used as the binder in cement products. Cement is a binding agent that sets and hardens to adhere to building units such as stones, bricks, tiles etc. 2: Clinker is a granular substance containing spherical pellets of diameter 325 mm.

An emphasis on the understanding of how an effective maintenance program represents a key factor in enabling the organization to gain a competitive and strategic edge in an intensely competitive market. Increase the knowledge of the participants obtaining the right techniques of technological systems and/or their reliability systems of the cement plant with the objective of improve the plant

Cement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product. Clinker occurs as lumps or nodules, usually 3 millimetres ( in) to 25 millimetres ( in) in diameter. It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stage.

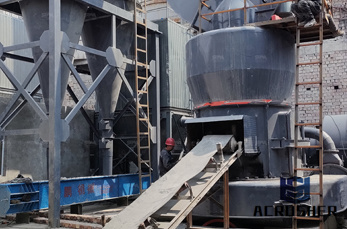

clinker grinding process in cement. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals.

#0183;#32;The share of Portland Slag Cement in cement production remained flat, at less than 10%, over the same period. The clinker factor reduced to in 2017 from in 2010. In August 2018 the Global Cement and Concrete Association (GCCA) said it was taking over the work previously done by the CSI from 1 January 2019.

#0183;#32;1. Introduction. Cement production belongs to one of the most energy intensive industrial processes in the world, which consumes about 34 GJ to produce a ton of clinker (Mirzakhani et al., 2017, Yin et al., 2016a) with a low thermal efficiency of below 54% (Atmaca and Yumruta, 2014b, Fellaou et al., 2018).Cement production consumes large quantities of thermal energy which accounts for 75%

WhatsApp)

WhatsApp)