grinding mill in iron ore

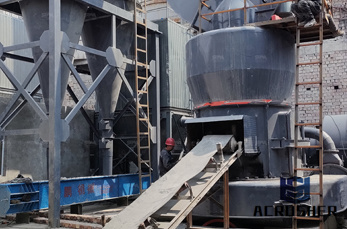

Research of iron ore grinding in a verticalrollermill ScienceDirect. Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here.

WhatsApp)

WhatsApp)

Research of iron ore grinding in a verticalrollermill ScienceDirect. Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here.

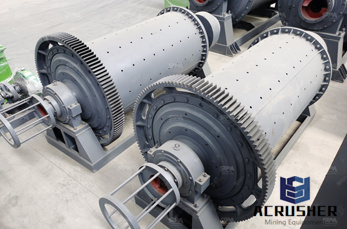

China Ball Mill Grinding Machinery catalog of 2016 High Quality Ball Mill / Ball Grinding Mill for Sale, EnergySaving Mineral Ore Cone Ball Mill (YMQ series) provided by China manufacturer Gongyi Hengchang Metallurgical Building Material Equipments Plant, page1.

400tph iron ore crushing line in Shanxi, China 3000,000TYP MTW138 Grinding Plant for heavy calcium in Zhejiang, China 9tph MTW138 Grinding Plant for coal powder processing in Jiangxi, China

Manganese ore production line processing technology. 121620; 3 Views; icon 0 . The process flow of processing manganese oxide ore mainly includes three processes of crushing, grinding and beneficiation. Generally, the ore is crushed to 60mm or 100mm, and then grouped, the coarse level is eliminated, and the fine level is sent to a shaker. .

Iron ore processing production line: Iron ore by the mining crusher preliminary broken in, to a reasonable size broken through after lifting machine, feeder evenly into the ball, the ore crushing, grinding by ball mill. After the ore fine grinding mill is expected to enter the next process: classification.

The ball mill is a key equipment for regrinding. It is widely used for the cement, iron ore beneficiation, gold ore beneficition, new type building material, fireproof material, chemical fertilizer, black and nonferrous metal, glass, ceramics and etc.. Our ball mill can grind ore or other materials that can be grinded either by wet process or by dry process.

iron ore grinding ball mill ba grinding ball mill in copper ore in rwanda. Ball mills are used for wet grinding iron ore g oldcopper ore nickel ore and other ores as wel l as limelimestone for flue gas desulphurisat ion systems coal and other raw materials Rod millWe are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other

Product Introduction A wet autogenous mill that materials as grinding media Feeding Particle Size 200350mm Product improvement Highefficiency autogenous mill can realize the second and third stage crushing and screening, and part or all crushing and grinding of rod mill or ball mil. Low power consumption, no dust pollution, less auxiliary equipment, easy production automation, and stable

Ball mill for grinding iron ore,coal,gold ore,copper ore,ball Ball mill is suitable for grinding all kinds of ores and other materials, no matter wet grinding or Ball Mill Iron

Ball or rod mills crush and grind the mined ore to fine particles that may be only microns (103 mm) in diameter, releasing molybdenite from the gangue (worthless rock). The grinding mills on the right reduce rocks the size of soccer balls to the size of gravel. Further ball milling reduces the material to the consistency of face price

Research of iron ore grinding in a verticalrollermill ScienceDirect. Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here.

Sep 28, 2017#0183;#32;Iron ore is an important raw material for iron and steel production enterprises. After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron

Iron Ore Vertical Grinding Machine Grinding Power. Iron Ore Vertical Grinding Mill Operation 2the ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silicates refractory material fertilizer glass ceramics etcs well as for ore dressing of both ferrous and

Gold Ore Ball Mill for Grinding Stone Gold ore ball mill for grinding stone Ball mill is the key recrush eqipment after the crushing. Ball mill is widely used in cement, silicate products, new building materials, refractories, chemical fertilizer, black and nonferrous metal oredressing, as well as the production industry of glass or ceramics, for carry though dry or wet grinding of a

Ore Grinding Ball Mill with Long Life Wear Parts for Minerals Gold Ore Flotation Production Line EPC FOB Price: US 130,000980,000 / Set. Min. Order: 1 Set Contact Now. Magnetite Separation Line for Iron Ore, Magnetite, Limonite, Hematite FOB Price:

ball mill grinding of iron ore economic feasibility. ball mill grinding of iron ore economic feasibility. There are forty years of manufacturing history, with three major production bases,over 160 senior Ramp;D engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectively

The iron ore separation line includes jaw crusher and hydraulic cone crusher for crushing, ball mill for grinding, magnetic separator for separation, and dryer for drying. View All. Brazil 200500tph crushing production line. Brazil''s crushing production line mainly consists of a mobile jaw crusher, a singlecylinder cone crusher and two

Then chromium ore would go into magnetic separation and flotation process. Ball mill plays an important role in the chromium beneficiation process. Grinding equipment selection has respect to the chrome ore beneficiation production efficiency. High Quality Ball Mill Used in South Africa Chromium Mining

WhatsApp)

WhatsApp)