Breaking down energy consumption in industrial grinding

The grinding process in ball mills is notoriously known to be highly inefficient: only 1 to 2% of the inputted electrical energy serves for creating new surfaces.

WhatsApp)

WhatsApp)

The grinding process in ball mills is notoriously known to be highly inefficient: only 1 to 2% of the inputted electrical energy serves for creating new surfaces.

Energy Consumption in Mining Comminution Jack Jeswiet*, Alex Szekeres Queens University, Kingston, Ontario, Canada (SemiAutogenous Grinding) or Ball mills. Crusher utilization average is 65% which is similar to equipment utilization in many manufacturing industries.

Grinding ball consumption in cement drive ball mills udcm type mills are designed to achieve maximum grinding efficiency, low energy consumption, compact plant layout and compact mill drive designll mill types may operate in either open or closed circuitdcm with its special design enables alternative drive systems by ouble pinion direct gearbox with girthgear.

consumption energy in grinding ball mill. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for anyel sizereduction requirements including quarry, aggregate, and different kinds of minerals.

Ball Mill Grinding Ball Consumption. The ball mills low grinding efficiency low processing capacity high production energy consumption and unstable product fineness are problems that most concentrators will encounter How to effectively improve the grinding efficiency of the ball mill is an important issue This article summarizes 10 ways to

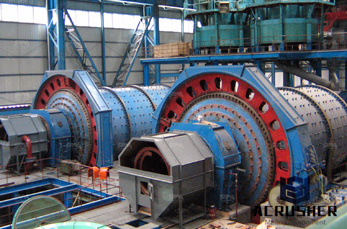

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

MODELLING THE SPECIFIC GRINDING ENERGY AND BALLMILL SCALEUP Ballmill scale up (Bonds Law)Data: zBond work index w i zFeed D f and product d size (both% cumulative passing) Result: The specific grinding energy w Mill power draw P = wT, where T the mill capacity Mill dimensions (from Tables or charts)

consumption energy in grinding ball mills. Calculation of energy required for grinding in a ball mill Abstract The Bond work index Wi as an indicator of the grindability of raw materials is not a material constant but rather it changes with change of size of the grinding product.

Effects Of Grinding Media Shapes On Ball Mill . Terms of energy requirements and steel consumption related to grinding media and liners spherical grinding media are predominantly used in final stages of ore grinding the spherical balls change shape through breakage and wear though this is universal in milling its contribution and effect on milling kinetics load behaviour and mill power

Fine Grinding With Impact Mills Chemical Engineering . Aug 01 The power consumption of the mill only is considered without classifier fan and other auxiliary units With the jet mill the jet power was used for the calculation and not the drive power of the compressor In the range of median finenesses between 10 and 100 181m the specific grinding energy is around 10 kWhmt mt metric ton.

Consumption Energy In Grinding Ball Mills . Ball Mill Design/Power Calculation Ball Mill Grinding Capacity Calculator Ball Mill Motor/Power Sizing Calculation Ball Mill Design/Sizing Calculator The power required to grind a material from a given feed size to a given product size can be estimated by using the following equation: where: W = power consumption expressed in kWh/short to (HPhr/short

Consumption of steel grinding media in mills a review consumption of steel grinding media in mills a review Grinding media consumption is one of the major operating costs in mineral processing industry it was found that the consumption of media in ball mills during grinding operation can be up to 50, consumption energy in grinding ball mill

Energy Consumption For Grinding Process Crusher E Port . How Does A High Pressure Energy Grinding Ball Mill Machine Highefficiency and low consumption with the same endproducts fineness and motor power its output is over 1 time of that of jet mill mix mill and ball millprocess diagnostic studies for cement mill important to optimise the existing mill installations as far as the grinding

how to calculate energy efficiency grinding mill Design Calculations Solar Powered Grinding Mills calculate the power that each ball mill ball mill and grinding efficiency, reduce energy consumption of . Read more

Energy saving with separate fine grinding. 13/10/2020 While ball mills are not the most energyefficient mills, VDZs research has shown that in some cases ultrafine grinding by means of a stirred media mill combines the advantages of a ball mill with low overall specific energy demand. By J Knappert, S Seemann and PM Fleiger, VDZ, Germany.

WhatsApp)

WhatsApp)