vertical roller mill for slag grinding YouTube

#0183;#32;Production of slag cement with an MPS vertical roller mill at the cement plant For this granulated blast furnace slag... SBM crushers and vertical mills for mineral slag processing plant.

WhatsApp)

WhatsApp)

#0183;#32;Production of slag cement with an MPS vertical roller mill at the cement plant For this granulated blast furnace slag... SBM crushers and vertical mills for mineral slag processing plant.

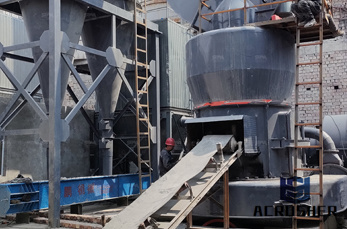

It is widely used in clinker grinding production of cement plant and slag grinding plant. CHAENG can provide various types of vertical cement mills with productivity of 50250t/h. The biggest advantage of CHAENG is to have a large casting base and large machining workshops, which greatly shortens the delivery cycle of cement vertical mill.

CHAENG GRMK cement vertical mill gathers grinding, drying and powder selecting as a whole, with high grinding efficiency and high drying capacity ( the maximum handling material moisture is up to 20% ).The vertical cement mill grind materials to related fineness by grinding rollers, you can easy adjusting your product fineness. it can call: Cement Mill, Vertical Cement Mill, Cement Vertical

offers 1,212 slag cement plant products. About 3% of these are Cement Making Machinery. A wide variety of slag cement plant options are available to you, such as warranty of core components, local service location, and key selling points.

#0183;#32;The grinding of clinker and cement and of granulated blast furnace slag and slag in vertical airswept grinding mills dates back to Ernst Curt Loesches invention. In 1927, he applied for a patent for the worlds first springloaded airswept mill the beginning of the triumph that is Loesche vertical roller mills.

#0183;#32;Belgium: Magotteaux has launched Expand, a vertical roller mill (WRM) wear parts product line for the cement industry. The equipment supplier says that the range offers high resistance, consistent production, energy efficiency and lower maintenance

LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology. Our designers are constantly coming up with new ideas and even more dependable components to reduce the already acclaimed low failure rate of our mills.

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc. Application : Cement Plant, Cl

Vertical Roller Mill is a new type advanced pulverizing equipment featuring good performance and drying function. Integrated with drying, pulverizing and powderselection, Vertical Roller Mill is widely applied in cement, chemical, coal and electric power industries.

Specializing in the sale of second hand cement plant equipment, and complete used cement plants. In addition to used and new surplus Cement Plant Equipment (rotary kilns, ball mills, vertical roller mills), NMI deals in many other types of machinery, including used equipment for Bulk Material Handling, Crushing, Grinding, Industrial Mineral Processing, and Power Plants

Grinding systems in cement production make up approximately 85 to 90 percent of total plant electrical energy consumption. As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to.

Complete Set Of Cement Production Line Provided By XinXiang Great Wall (CHAENG), Equipments For Cement,Mining,Provide GGBFS Plant|Mining Mill|Slag Mill|Vertical Roller Mill| Cement Tube Mill | Ball Mill | Grinding Equipments | Cement Rotary Kiln.

Turnkey Cement Plant Cement Production Line 500 t/d Cement Plant 700 t/d Cement Plant 1000 t/d Cement Plant 1500 t/d Cement Plant 2500 t/d Cement Plant Solutions for Cement Grinding Plant Active Lime Production Line Cement Plant Clinker Grinding station Steel Mill Thermal Power Plant GGBFS Production Line 300,000 t/a GGBFS Plant 450,000 t/a

#0183;#32;CEMENT PLANT FOR SALE. TWO METPROTECH STIRRED VERTICAL BALL MILLS 400/2000 with Flender. gearboxes. The 400 is the KW power of the GEC Alsthom motors, which are 11000 volt. Asssembled in Australia in 1994 then shipped to New Zeland where they were used for 2230 hours . OTHER MILLS AVAILABLE: 45,000 TONS PER DAY PROCESSING PLANT:

CHAENG | Great Wall Machinery provides you:Slag Grinding Plant,Cement Equipment,Vertical Mill,Ball Mill,Rotary Kiln For Quarry, Mining, Construction,Slag Processing

While producing slag cement CEM III A with 40% slag at a fineness of 5500cm#178;/g, the throughput could be increased by 30% and the specific power consumption of mill, separator and fan was reduced by more than 10% after the modernisation of the plant. Today more than 30 MPS vertical roller mills of the BC series for slag, cement and binding

WhatsApp)

WhatsApp)