(PDF) MECHANICAL COMPORTEMENT OF A CEMENT

rotary cement kiln using artificial neural networks, 30 (2009) . [5] Bernard Gilbert, Alain Regnault, Fours de cimenterie, four rotatif, BE 8845 Editions techniques de ling#233;nieur.

WhatsApp)

WhatsApp)

rotary cement kiln using artificial neural networks, 30 (2009) . [5] Bernard Gilbert, Alain Regnault, Fours de cimenterie, four rotatif, BE 8845 Editions techniques de ling#233;nieur.

And advanced seal technology is used in kiln head and kiln tail. Rotary Kiln For Ceramsite Working Principle . The barrel of rotary kiln for ceramsite has a slope of 3%4% with a horizontal plane. The kiln body is immobilized in wheel gear by twowheel band. The principle of rotation is that inverter motor drives the pinion to rotate through reducer and its associated coupling. Then gears mesh

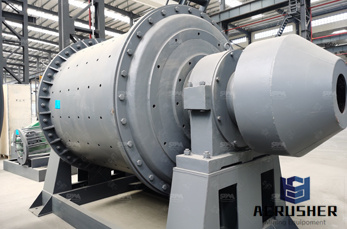

Rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. Raw materials after grinding will be burned into clinker under the action of high temperature of cement rotary kiln. Hence, cement rotary kiln also is commonly known as the heart of cement plant. Structure of Rotary Kiln

The oxygen enrichment technology is established in some cement plants in order to improve production capacity. An increase of 25% to 50% (short term experiments) rotary kiln capacity by oxygen enrichment to 3035 vol.% in the combustion air has been reported. Oxygen enrichment has not been applied to reduce CO2 emissions so far. But the use of enriched combustion air may result in fuel savings

Rotary kiln is thermal equipment to heat materials. It is widely used in the fields of cement, nonferrous metallurgy, ferrous metallurgy, refractory material, chemical, and makingpaper. We produce other kilns with the diameter 15 meters and widely applied in the metallurgy, chemical industry and so on. This kind of kilns supporting is divided into two forms of rolls and skids. The

Rotary kiln is also known as lime rotary kiln. According to different processed materials, rotary kiln can be divided into cement kiln, metallurgy chemical kiln and lime kiln. It is mainly used for calcining cement clinker and can be classified into production of dry cement kiln and wet cement kiln .Rotary kiln is widely applied into building materials, metallurgy, chemical industry

The kiln is set at a slight slope to assist in moving material through the drum. According to the material types to be processed, the rotary kiln can be divided into cement kiln, metallurgical chemistry kiln, and limestone kiln. Rotary Kiln Features: 1. Advanced structure, good sealing, the kiln head is sealed by the shell, and the kiln tail

Gypsum rotary kiln is an industrial equipment, which can make a lot of production. And the production of gypsum has a great role, mainly used for construction of building engineering, pharmacological treatment, mold processing, chemical industry, cement regulation in many areas, almost became the indispensable in peoples daily life products, so it has a very deep value.

The rotary kiln is composed of cylinder, supporting device, supporting device with baffle wheel, transmission device, movable kiln head, sealing device of kiln tail, coal injection pipe device, etc. The kiln body of the wet rotary kiln is inclined to a certain level. The whole kiln body is supported by a supporting wheel device and has a wheelretaining device to control the movement of the

German Kiln Technology (GKT) is an international specialist amp; manufacturer for kilns in advanced amp; technical ceramic markets. GKT has joined the market bringing with it a tradition of competence and skill. GKT engineers with over 20 years of experience and knowhow in the ceramic industry can focus all of its capabilities towards the development of outstanding solutions for the

WhatsApp)

WhatsApp)