ball mill working principle YouTube

#0183;#32;Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

WhatsApp)

WhatsApp)

#0183;#32;Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

#0183;#32;Vibration mills are similar to ball mills in that particles of the materials are crushed between porcelain or metal balls and the mill body. Drugs and excipients are readily ground to less than 5 mm, the grinding time being considerably less than is required in normal ball milling.

#0183;#32;Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ball...

Download Citation | Vibration characteristics for reflecting level of coal powder filling in an industrial tubular ball mill | To achieve improvements in the production capacity and energy

Labeltube conveyor ZM single tube vibration mill. IntroduceZM series single tube vibration mill is a new type of high efficient energy saving powder grinding equipment. It has obvious advantages over traditional rotary mill tools when grinding fine powder and u... Labelvibration mill GX tube

1A BALL MILL, WAVEFORM LEVEL, LOADED VS UNLOADED, SEPTEMBER 2010 WAVENO LOAD WAVELOADED Above is a plot of the waveform vibration levels at 1A ball mill when loaded amp; unloaded. Note the significant difference that loading makes on vibration levels at this machine.

pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner panels.

#0183;#32; pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner panels.

At present the method for measuring the fill level which used the vibration signal of mill shell shows its advantage compared with other methods. However, this method is developed late, and the technique for collecting the vibration signal from mill shell is immature. In this paper, a novel method for collecting the vibration data from mill shell is proposed.

Xinxiang Yihu Machinery Equipment Co.,Ltd is an innovative enterprise integrated with technology research, manufacture and trade. Our enterprise is professional in Conveyor, hoist, vibrating screen, feeding machine, mixer, dustproof equipment etc. We are committed to developing and researching a complete set of solutions for powder material treatment.

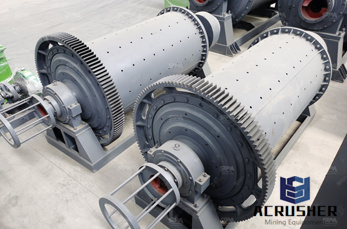

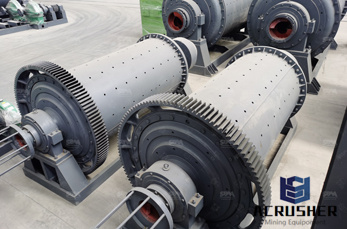

Several types of ball mills exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball mills.

than of a twintube vibration mill with the same tube diameter. The highest capacity, with a lower degree of fineness, is achieved by medium size feeding material in three cylinders (4) ( for the production of sand during grinding). This operating method involves short grinding procedures, resulting a

Aerated ball tube mills are designed for anthracites, coal, lignite, shale and other materials grinding up to pulverized condition and for continuous operation in coal pulverization systems at thermal power plants and other branches of industry.

Maintaining Mill Power up to 1700 KW by ball charging. Forged Steel Balls replaced with Hichrome Balls for consistency in Mill Power. (This has been done in seven Mills and another three Mills shall be converted in 201314). Whenever any Raw Coal Feeder of a Mill with blended coal feeding

Types of coal pulverizers. Coal pulverizers may be classified by speed, as follows: Low Speed; Medium Speed; High Speed; Low speed Ball and tube mills. A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods.

Planetary ball mills are smaller than common ball mills, and are mainly used in laboratories for grinding sample material down to very small sizes. Vibration mill. Twin and threetube vibrating mills are driven by an unbalanced drive.

WhatsApp)

WhatsApp)