How the Iron Ore Market Works (VALE, RIO)

#0183;#32;Mines in Michigan and Minnesota account for the bulk of iron ore production in the United States. In 2019, mines produced 48 million metric tons of iron ore.

WhatsApp)

WhatsApp)

#0183;#32;Mines in Michigan and Minnesota account for the bulk of iron ore production in the United States. In 2019, mines produced 48 million metric tons of iron ore.

Ore Ore Crusher Aggregate Crushing Plant Layout. Our sand production line mainly consists of vibrating feeder, jaw crusher, sand making machine, vibrating screen, sand washing plant, belt conveyor, electric control panel, etc, and capacity is 50500T/H. Our sand production line is taking the leading role in the sand making industry.

Global iron ore production will grow from 2,896mnt in 2019 to 3,147mnt by 2029, Fitch forecasts. This represents an average annual growth rate of % during, which is a signicant

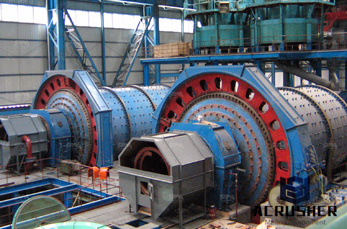

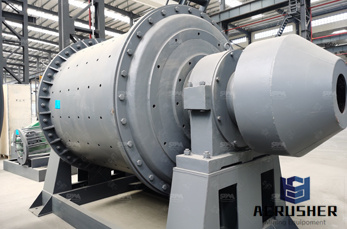

Production Process of Iron Ore Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc. The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Mill Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and Dryer. And Equipped with Feeder, Elevator and Conveyor, a full set of

US iron ore mining is dominated by the Precambrian banded iron formation deposits around Lake Superior, in Minnesota and Michigan; such deposits were also formerly mined in Wisconsin. For the past 50 years, more than 90 percent of US iron ore production has been mined from the Lake Superior deposits. None of the iron ore now mined in the US is direct shipping ore ready to be fed into the iron

#0183;#32;Vale (NYSE: VALE) is maintaining its production target of approximately 310 million tonnes of iron ore in 2020, chief financial officer Luciano Siani Pires said in an interview with Bloomberg...

#0183;#32;Global iron ore production will grow from 2,896mnt in 2019 to 3,147mnt by 2029, Fitch forecasts. This represents an average annual growth rate of

Iron ore production line Sanme Mining Machinery Crusher. SANME is capable of producing complete equipments for mineral aggregate crushing and offering comprehensive technical support.

Iron ore processing production line: Iron ore by the mining crusher preliminary broken in, to a reasonable size broken through after lifting machine, feeder evenly into the ball, the ore crushing, grinding by ball mill. After the ore fine grinding mill is expected to enter the next process: classification.

#0183;#32;Ironore mining (Wikimedia Commons) In a big boost for iron ore mining in Karnataka, the activity is set to resume at Donimalai mines after it was shut down for

#0183;#32;The iron ore is exported from the port by a fleet of four transshipping vessels. Other infrastructure facilities at the Pepel Port include two stockpile material handling facilities, a 160person camp, and a dredging facility. Financing. The first phase of the iron ore mining project received 100m of subordinated standby facility from Standard Bank.

The world''s largest producer of iron ore is the Brazilian mining corporation Vale, followed by AngloAustralian companies Rio Tinto Group and then BHP.

#0183;#32;Diversified AngloAustralian mining company Rio Tinto tops our list with iron ore production of 327 million tonnes in 2019. Snatching top spot from previous leader Vale was not only due to the Brazilian companys political and economic turmoil but also Rio Tinto initiatives, such as investing in automation and reassuring stakeholders with consistent mining investments and developments.

#0183;#32;The iron ore is exported from the port by a fleet of four transshipping vessels. Other infrastructure facilities at the Pepel Port include two stockpile material handling facilities, a 160person camp, and a dredging facility. Financing. The first phase of the iron ore mining project received 100m of subordinated standby facility from Standard Bank.

Iron Ore Processing Production Line GitHub Pages. Iron ore processing production line by the jaw crusher, ball mill, classifier, magnetic separator, flotation machine, thickener and dryers and other major components for I prepared with beneficiation production lines, feeder, hoist, conveyor can

Newcastle milling production line processing iron ore : A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial finished product can be controlled freely from 0 to 3000 mesh.

Iron Ore,Production Process of Iron Ore,Iron Ore

WhatsApp)

WhatsApp)